Advancements in Modern Bolt and Thread Rolling Machines in India

Author : samratenggworks samratenggworks | Published On : 10 Oct 2025

The evolution of manufacturing technology in India has significantly shaped the metalworking sector. From simple manual processes to advanced automation, industries have embraced innovation to meet rising demands for precision and efficiency. Among the critical advancements are machines designed for shaping bolts and threads—components vital across construction, automotive, and industrial applications. The continued enhancement of production capabilities reflects the nation’s growing engineering expertise, with machinery now delivering not only strength and accuracy but also consistency and speed in every production cycle. This evolution has created a landscape where efficiency meets precision seamlessly.

Precision in Motion: Role of Bolt Making Machine Manufacturers In India

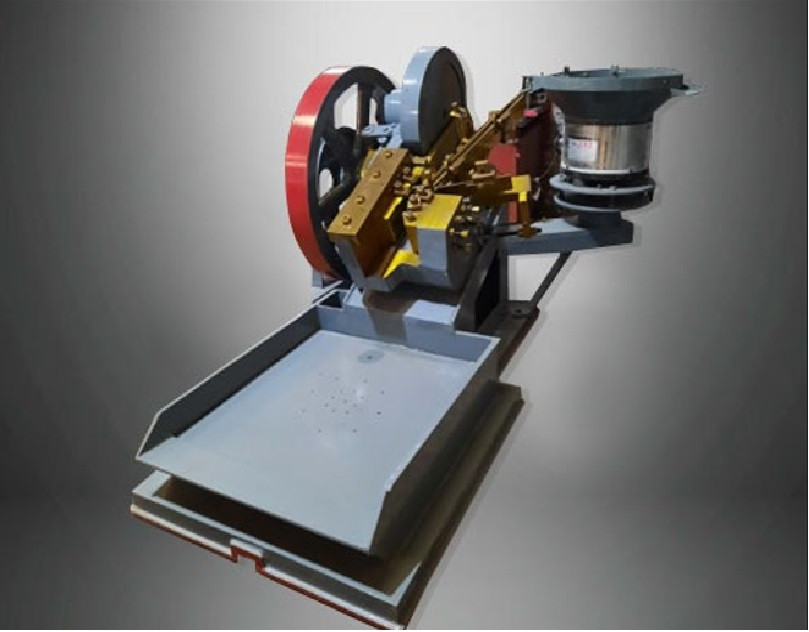

Modern Bolt Making Machine Manufacturers In India are transforming production methods by integrating high-performance technology into their systems. These machines are engineered to handle various grades of steel, ensuring uniformity and tensile strength in every bolt produced. Manufacturers focus on durability, reduced maintenance, and advanced automation features that enhance productivity. As demand for fasteners continues to grow across multiple sectors, Indian manufacturers are refining their designs to cater to global quality standards. The focus on innovation, combined with precision mechanics, has positioned these machines as reliable tools in both domestic and international markets.

Engineering Perfection: Thread Rolling Machine Ludhiana Innovations

The city of Ludhiana, long known as a manufacturing hub, plays a vital role in India’s machine tool evolution. The Thread Rolling Machine Ludhiana is a product of this industrial excellence, crafted with meticulous engineering that ensures flawless threading with minimal material waste. These machines employ cold-forming technology, which enhances the structural integrity of fasteners by improving their surface finish and mechanical strength. The precision and repeatability achieved in each cycle make them an essential asset for industries demanding reliability in mass production. Ludhiana’s manufacturers continue to innovate, aligning their machines with modern production requirements.

Nationwide Expertise: Thread Rolling Machine Supplier in India

Every Thread Rolling Machine Supplier in India plays a crucial part in bridging the gap between advanced manufacturing technology and industrial demand. Suppliers provide a diverse range of machines suitable for different thread profiles, diameters, and materials. They ensure each machine is supported with proper technical documentation, operational training, and after-sales service, allowing seamless integration into production facilities. The collaborative approach of suppliers has strengthened the industrial supply chain, promoting quality-driven outcomes across sectors. By consistently delivering reliable machinery, these suppliers contribute to India’s reputation as a growing hub for mechanical innovation and manufacturing excellence.

Automation Revolution: Fully Automatic Thread Rolling Machine in India

The introduction of the Fully Automatic Thread Rolling Machine in India marks a defining step toward enhanced industrial productivity. These machines are designed to function with minimal human intervention, achieving faster production cycles without compromising accuracy. Equipped with digital control panels, hydraulic systems, and automated feeding mechanisms, they optimize workflow efficiency while ensuring safety and precision. Such machines are increasingly preferred by industries focused on large-scale, high-speed operations. The seamless integration of automation technology showcases India’s transition into advanced manufacturing ecosystems capable of meeting the challenges of global competitiveness.

Conclusion: The Future of Industrial Machinery in India

The machinery sector in India stands at the forefront of continuous evolution, with innovation shaping the future of fastener production. The advancements in bolt and thread rolling machines demonstrate how engineering precision and automation can coexist to drive manufacturing excellence. As industries move toward smarter production models, these machines are expected to become more adaptive, efficient, and resource-conscious. The growing emphasis on technology and reliability ensures that India’s machinery landscape will continue to strengthen its global footprint while meeting the diverse demands of the modern industrial era.