Unlock Your Machinery's True Potential The Power of Precision Measurement with Next-Gen Dynamometer

Author : McDowell Brooks | Published On : 15 Nov 2025

Ever felt like you're flying blind when testing your engines, motors, or powertrains? You pour resources into development, push for peak performance, and strive for ultimate efficiency, but there's always that nagging doubt: *Do you truly know what your machine is capable of under real-world conditions?* Are you relying on estimations, theoretical models, or outdated testing methods that leave critical data points hidden in the shadows? It’s like tuning a high-performance race car based solely on the sound of the engine, ignoring the actual torque hitting the wheels. That gap between perceived performance and actual, measurable output is where opportunities vanish and costly surprises emerge. It’s the difference between *thinking* you have a winner and *knowing* it beyond a shadow of a doubt. ��

Enter the unsung hero of engineering validation: **The Dynamometer**. Often simply called a "dyno," this sophisticated instrument isn't just another piece of lab equipment gathering dust. It’s the critical bridge between design aspiration and operational reality. Think of it as the ultimate truth-teller for any rotating machinery, from the smallest precision electric motors humming in medical devices to the colossal diesel engines propelling container ships across oceans, and the cutting-edge electric drive units accelerating tomorrow's EVs. ⚡��️

**Beyond Horsepower Hype: What a Modern Dynamometer *Really* Does (And Why It Matters)**

Forget the simplistic image of dynos just spitting out peak horsepower and torque numbers for muscle car bragging rights. While those headline figures are important, the true value of a state-of-the-art dynamometer lies in its profound depth and breadth of insight. It’s a comprehensive measurement and simulation powerhouse:

1. **Precision Quantification of Power u0026 Torque:** This is the fundamental job. But modern dynos deliver this with astonishing accuracy, stability, and repeatability across the entire operating range. No more guesswork. No more approximations. You get the cold, hard facts about how much twisting force (torque) your machine produces and how effectively it translates that into usable power (horsepower or kilowatts) at any given speed. �✅

2. **Mapping the Entire Performance Envelope:** A dyno doesn't just measure peak values. It meticulously maps performance curves – torque vs. speed, power vs. speed, efficiency vs. load. Visualizing this map is crucial. Where is the torque peak? How flat is the curve? Where does efficiency plummet? Understanding these nuances is paramount for optimizing design, identifying sweet spots, and avoiding problematic operating zones. �️�

3. **Efficiency Under the Microscope:** In an era demanding sustainability, raw power isn't enough. How efficiently is that input energy (fuel, electricity) converted into useful mechanical work? Dynamometers provide precise measurements of input vs. output power, enabling detailed efficiency calculations. Pinpointing energy losses (heat, friction, electrical) becomes possible, directly guiding improvements that save money and reduce environmental impact. ♻️�

4. **Controlled Environmental Simulation:** This is where advanced dynos truly shine. They don't just measure; they *simulate*. Need to test how your marine engine performs under full load at 95% humidity and 40°C? Or how your EV motor controller behaves during rapid regenerative braking cycles at -20°C? A sophisticated dynamometer system, coupled with environmental chambers and advanced control software, can replicate these exact conditions in the lab. Test what was previously untestable without expensive field trials. �️❄️�

5. **Durability u0026 Endurance Testing Accelerated:** How will your transmission hold up after 100,000 simulated miles? Can that new compressor motor withstand a decade of daily start-stop cycles? Dynamometers enable accelerated life testing by applying precise, controlled loads and cycles far beyond normal operation, 24/7, compressing years of wear into weeks or months of testing. Identify weaknesses before they reach the customer. ⏱️�️

6. **Dynamic Response Analysis:** How quickly does an engine respond to a sudden throttle demand? Does a servo motor precisely follow a complex motion profile? Modern dynamometers, especially AC motoring dynos with high-bandwidth control, can measure transient response with millisecond precision, critical for applications demanding agility and precision, from robotics to performance vehicles. ⚡�

7. **Emissions Development Support:** Engine dynamometers are fundamental tools in emissions development. By precisely controlling engine load and speed while measuring exhaust gases, engineers can map emissions behavior, calibrate after-treatment systems (like catalysts and DPFs), and ensure compliance with increasingly stringent global regulations. ��☁️

**Cutting Through the Noise: Key Innovations in Modern Dynamometry**

Dynamometer technology isn't static. It’s evolving rapidly to meet the demands of new propulsion systems, higher efficiencies, and faster development cycles. Here’s what sets the latest generation apart:

* **AC Motoring Dynamometers Reign Supreme:** Move over, old-school hydraulic and DC dynos. Advanced AC regenerative dynamometers are now the benchmark. Why? They offer unparalleled control accuracy, bidirectional operation (motoring *and* absorbing), incredible low-speed torque capability, minimal inertia, and the ability to feed regenerated energy back into the grid – slashing operating costs and cooling requirements. They are essential for testing hybrid and electric powertrains, simulating realistic driving cycles, and capturing regenerative braking energy. �♻️

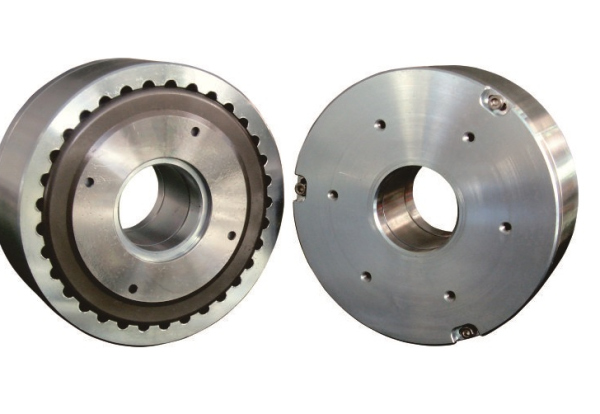

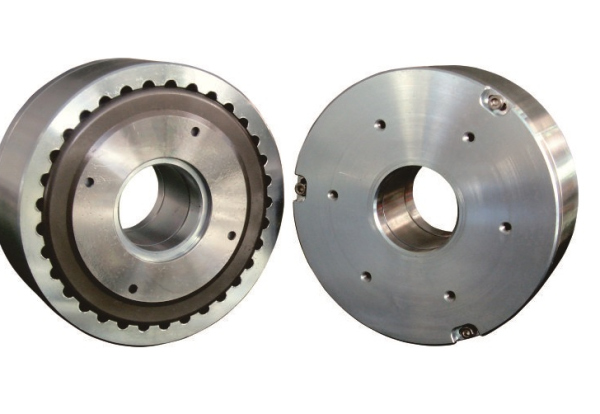

* **High-Fidelity Data Acquisition u0026 Control:** Modern dynos are digital powerhouses. High-speed, high-resolution data acquisition captures every nuance of performance – torque ripple, vibration frequencies, electrical harmonics – at rates far exceeding traditional systems. hysteresis brake ensure load points are held with rock-solid stability, even during aggressive transients.

* **Integrated Simulation Capabilities:** The most advanced systems go beyond simple load application. They integrate real-time simulation models of the complete vehicle or driven system (using tools like Simulink or dedicated HIL platforms). This allows for "virtual vehicle" testing on the dyno, evaluating how an engine or motor performs within the context of the entire drivetrain, vehicle dynamics, and driver behavior, all within the controlled lab environment. �️�

* **Cybersecurity u0026 Connectivity:** As dynos become networked and integrated into broader test cell automation and data management systems, robust cybersecurity features are paramount. Secure data transfer, remote monitoring capabilities, and compatibility with modern Manufacturing Execution Systems (MES) or data lakes are increasingly standard requirements.

* **Versatility u0026 Modularity:** The best platforms offer incredible flexibility. Easily swap adapters to test anything from a small drone motor to a large industrial diesel. Add modules for emissions measurement, vibration analysis, thermal imaging, or battery simulation. A well-designed dyno system grows with your evolving testing needs. �

**Real-World Impact: Where Precision Measurement Drives Success**

The applications for dynamometers are vast and touch nearly every sector involving rotating machinery:

* **Automotive u0026 Motorsport:** Engine development, calibration (fuel mapping, boost control, ignition timing), transmission testing, driveline NVH analysis, electric drive unit (EDU) validation, battery pack simulation, brake dyno testing, homologation. From OEMs to niche tuners, dynos are indispensable for pushing the limits of performance, efficiency, and reliability. Winning races and topping fuel economy charts both start on the dyno. ���

* **Aerospace:** Testing auxiliary power units (APUs), jet engine starters, actuators, flight control systems, and increasingly, components for hybrid-electric and fully electric aircraft propulsion. Reliability and safety here are non-negotiable. ✈️

* **Marine u0026 Locomotive:** Validating massive propulsion engines, thrusters, generators, and traction motors under realistic load profiles. Fuel consumption savings here translate into massive operational cost reductions. ⚓�

* **Industrial Machinery u0026 Pumps:** Testing motors, gearboxes, compressors, pumps, and fans. Optimizing efficiency, ensuring reliability for critical processes, and validating performance before installation. �

* **Electric Motors u0026 Drives:** From tiny servos to massive industrial motors and cutting-edge EV traction motors. Characterizing torque-speed curves, efficiency maps (especially crucial for inverter-driven motors), thermal performance, and dynamic control response. Precise dyno testing unlocks optimal motor design and drive control strategies. �⚙️

* **Renewable Energy:** Testing wind turbine gearboxes and generators, validating hydraulic systems for wave/tidal power, and assessing components for next-generation energy storage solutions. �️�

* **Research u0026 Academia:** Pushing the boundaries of knowledge in combustion, electromagnetics, materials science, and control theory. The dyno is a fundamental tool for discovery and innovation. ��

**Choosing Your Partner in Precision: What Truly Matters**

Investing in a dynamometer is a significant decision. It’s not just about buying hardware; it’s about forging a partnership to achieve your testing goals reliably for years to come. Look beyond the spec sheet:

* **Application Expertise:** Does the supplier *deeply* understand *your* specific testing challenges? Can they provide proven solutions in your industry? Ask for detailed references and case studies. Partner with engineers who speak your language.

* **Accuracy u0026 Traceability:** Insist on clear specifications for torque, speed, and power measurement accuracy. Demand comprehensive calibration certificates traceable to national standards (NIST, NPL, PTB, etc.). Accuracy is the bedrock of trust in your data. �

* **Control Performance:** Stability and dynamic response are critical. Ask for metrics on control bandwidth, torque ripple, speed stability under load, and step response times. Don't just accept vague promises.

* **System Integration:** How seamlessly will the dyno integrate with your existing test cell infrastructure – cooling, ventilation, electrical supply, data acquisition (DAQ), control software, safety systems? A good supplier manages the entire system integration. �

* **Software u0026 Usability:** The control and data acquisition software is your primary interface. Is it intuitive? Powerful? Flexible? Can it handle complex test sequences, automate reporting, and integrate with other analysis tools? Clunky software cripples productivity. �

* **Regenerative Capability u0026 Efficiency:** For AC motoring dynos, understand the true regenerative efficiency – what percentage of absorbed power is actually fed back cleanly to the grid? This dramatically impacts operating costs (electricity and cooling). True regeneration is a game-changer.

* **Service u0026 Support:** Where are the service engineers located? What are response times? Is training comprehensive? Robust, readily available technical support is essential for minimizing downtime. Look for a partner with a global footprint and a reputation for reliability.

* **Future-Proofing:** Is the system designed with modularity? Can it accommodate future upgrades – higher power, different fuel or energy sources (hydrogen, e-fuels), new measurement technologies? Think long-term.

**Beyond the Numbers: The Strategic Advantage**

Implementing a sophisticated dynamometer isn't just an operational expense; it’s a strategic investment with profound long-term benefits:

* **Accelerated Time-to-Market:** Identify and resolve issues *early* in the development cycle. Compress validation timelines through precise, repeatable testing and simulation. Get superior products to market faster than competitors. ⏩

* **Substantial Cost Savings:** Avoid costly field failures, warranty claims, and recalls. Optimize designs for maximum efficiency, reducing operational costs for end-users (fuel/electricity). Slash energy bills through regeneration. Minimize prototype iterations. �

* **Uncompromising Quality u0026 Reliability:** Deliver products that work as designed, consistently, under all specified conditions. Build a reputation for durability and dependability that wins customer loyalty and commands premium pricing. �️

* **Data-Driven Innovation:** Gain deep insights that fuel genuine innovation. Understand the "why" behind performance, not just the "what." Use empirical data to challenge assumptions and explore new design frontiers. �

* **Compliance Confidence:** Navigate the complex landscape of global emissions and efficiency regulations with certainty. Generate the auditable data required for certifications and approvals. ✅

* **Competitive Edge:** In a world obsessed with performance and efficiency, possessing the tools to measure, understand, and optimize these parameters with unmatched precision provides a fundamental competitive advantage. Out-test, out-innovate, outperform. �

**The Final Word: Stop Guessing. Start Knowing.**

In the relentless pursuit of engineering excellence, ambiguity is the enemy. Assumptions are vulnerabilities. Estimates are risks. A modern, high-performance dynamometer system, chosen and implemented wisely, banishes these uncertainties. It transforms your test lab from a place of verification into a powerhouse of innovation, optimization, and absolute confidence.

It empowers you to push boundaries safely, validate claims rigorously, and deliver machinery that doesn't just meet specifications but defines them. It gives you the hard, undeniable data to back up your boldest ambitions. �

Don't let your next breakthrough be limited by measurement limitations. Embrace the precision, versatility, and power of next-generation dynamometry. Connect the dots between your engineering vision and its tangible, measurable reality.

Ready to unlock the true potential of your machines and leave the competition measuring shadows? The most valuable insights are waiting to be measured. What will you discover? ��