The Unseen Force Powering Precision How Hysteresis Brakes Revolutionize Motion Control �c

Author : West Severinsen | Published On : 17 Nov 2025

Ever stop to consider the silent heroes within the machines shaping our world? While flashy motors and complex controllers grab attention, there's an unsung maestro working tirelessly behind the scenes, ensuring smooth stops, precise tension, and controlled motion: the hysteresis brake. Forget the clang and grind of traditional friction brakes. This is control redefined by the elegant dance of physics. It's time this technological marvel stepped into the spotlight. ✨

Imagine a braking force that emerges silently, predictably, and without a single moving part touching another. That's the magic of hysteresis. Derived from the Greek word "hysteresis," meaning "lagging behind," it describes a fascinating property of magnetic materials. When exposed to a magnetic field, these materials resist the change. They "lag." And it's precisely this magnetic reluctance that we harness to create smooth, controllable braking torque. Think of it as the material's inherent magnetic memory creating frictionless resistance. ��

**Why Friction Brakes Are Stuck in the Past (and Why You Should Care) ��**

Traditional friction brakes rely on physical contact – pads clamping onto discs, shoes pressing against drums. It’s a concept as old as the wheel itself. While functional, this approach comes with significant baggage:

1. **The Wear and Tear Tango:** Constant friction means constant degradation. Pads wear down, discs score, drums warp. This isn't just an annoyance; it's a relentless drain on maintenance budgets, production downtime, and component replacement costs. Your machine is literally grinding itself away.

2. **Torque Troubles:** Achieving consistent torque? Good luck. Friction coefficients change dramatically with temperature, contamination (oil, dust, moisture), and wear. What starts as a precise braking force can quickly become erratic and unreliable. Consistency is the enemy of friction.

3. **The Torque-Temperature Tango (or Nightmare):** As friction brakes heat up during operation, their performance plummets. Braking force fades, sometimes dangerously. This "brake fade" limits duty cycles and introduces a critical safety variable that's hard to predict perfectly.

4. **Noise Pollution Symphony:** The screech of metal-on-metal is an industrial anthem, but it's one nobody wants to hear. Friction brakes generate significant noise pollution, contributing to an unpleasant and potentially unhealthy work environment. �

5. **The Dust Dilemma:** All that grinding creates debris. Brake dust isn't just messy; it can contaminate sensitive processes, foul sensors, and damage other machine components, adding another layer of maintenance woe.

**Hysteresis Brakes: Where Physics Becomes Your Silent Partner ���**

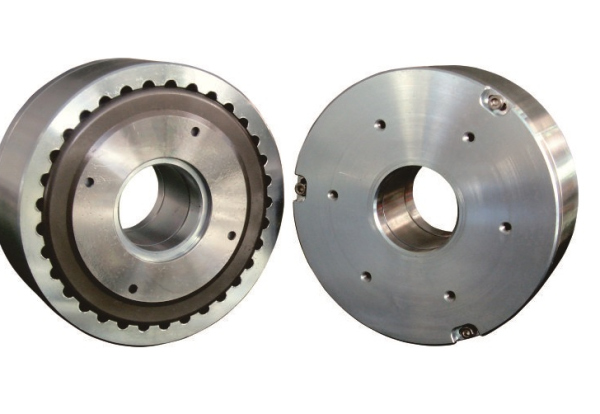

Hysteresis brakes operate on a fundamentally different principle: magnetism. No physical contact. No grinding. Just pure, controllable magnetic force. Here's the core anatomy:

* **The Rotor:** Typically a smooth disc made of a special alloy with high magnetic hysteresis properties. This is the only moving part.

* **The Stator:** Houses electromagnetic coils. When energized, these coils generate a powerful magnetic field.

* **The Air Gap:** The critical, consistent space separating the stationary stator and the rotating rotor. *No contact occurs here.* The magnetic field bridges this gap.

**The Magic Happens Like This:**

1. You apply a controlled electrical current to the stator coils.

2. The coils generate a proportional, controlled magnetic field.

3. This magnetic field penetrates the air gap and magnetizes the rotor material.

4. Due to hysteresis, the rotor material resists being magnetized. As the rotor spins, it constantly tries to align its internal magnetic domains with the stator's field, but it lags behind. This internal molecular friction within the rotor material itself – *not surface friction* – generates a smooth, consistent drag torque.

5. The magnitude of this torque is directly proportional to the strength of the magnetic field, which is directly proportional to the input current. More current = more torque. Less current = less torque. Simple. Linear. Predictable. �

**Unlocking the Treasure Trove of Advantages �️�**

The shift from friction to hysteresis unlocks a cascade of performance and operational benefits:

1. **Zero Wear, Infinite Life (Practically):** This is the game-changer. With no physical contact, there is *no mechanical wear* on the braking components. The rotor and stator remain pristine. Your maintenance headaches vanish. Component life extends dramatically, often for the entire lifespan of the machine itself. This translates directly to lower Total Cost of Ownership (TCO) and maximized uptime. ✅

2. **Exquisite Torque Control:** Precision is the name of the game. Torque output is directly proportional to the input current. Adjust the current with fine granularity (via a simple controller), and you adjust the braking torque with matching precision. This linear relationship holds true regardless of speed. Need 0.1 Nm? 10 Nm? 100 Nm? It's just a matter of dialing in the right current. Consistency is guaranteed. �

3. **Silence is Golden:** Operating with zero physical contact means near-silent operation. The primary sound is often just the gentle whir of air moving around the rotor. This drastically reduces noise pollution, creating a better work environment and meeting stricter noise regulations effortlessly. �

4. **Speed Agnostic:** Friction brakes often struggle at very low speeds (stick-slip) and can be harsh or inconsistent at high speeds. Hysteresis brakes deliver smooth, consistent torque from zero RPM all the way up to their maximum rated speed. This is crucial for applications requiring controlled tensioning or smooth deceleration across the entire speed range. ⏩⏪

5. **Cool Under Pressure:** Since the braking force comes from internal magnetic hysteresis *within* the rotor material, not surface friction, heat generation is significantly lower and more evenly distributed. There's no dramatic surface temperature spike or brake fade. Duty cycles are longer, and performance remains stable. ❄️� (Mostly the ❄️!)

6. **Contaminant Immune:** Grease, oil, dust, moisture – the nemeses of friction brakes – have virtually no effect on a hysteresis brake's performance. Its torque is generated magnetically across an air gap. This makes them ideal for harsh environments like food processing, printing, textile manufacturing, or outdoor applications. ��️��️

7. **Smooth Operator:** The nature of hysteresis torque produces a buttery-smooth drag. There's no grabbing, jerking, or chatter. This is essential for applications involving delicate materials (films, fibers, wires) or processes requiring ultra-precise tension control and vibration-free operation.

**Where Hysteresis Brakes Truly Shine: Real-World Impact �⚙️**

The unique advantages of hysteresis brakes make them indispensable across a surprising breadth of industries:

1. **Tension Control Mastery:**

* **Web Handling (Printing, Converting, Packaging):** Maintaining perfect, consistent tension as paper, film, foil, or fabric unwinds from a roll, travels through presses, coaters, laminators, or slitters, and rewinds is paramount. Hysteresis brakes provide the precise, smooth, and speed-independent torque needed to prevent wrinkles, tears, misalignment, and splices from popping. A wrinkled magazine cover or misaligned food packaging? Often a tension control failure prevented by hysteresis. �️�

* **Wire u0026 Cable Production:** Drawing copper, applying insulation, coiling cable – all require precise tension control to ensure consistent diameter, prevent kinking, and enable smooth winding onto spools. Hysteresis brakes deliver this precision reliably on fast-moving lines.

* **Fiber Optics u0026 Filament Winding:** Handling delicate glass fibers or carbon filaments demands ultra-smooth, jerk-free tension. The silent, vibration-free operation of hysteresis brakes is perfect for these sensitive processes.

2. **Dynamometer Duty (Absorbing Power):** Engine, motor, and transmission test stands need to absorb power and provide controlled loading. Hysteresis brakes offer excellent speed regulation, precise torque control, and high-speed capability, making them ideal for characterizing performance under various load conditions. �️�

3. **Overhauling Load Safety (Preventing Runaway):** In applications where gravity can cause a load to "overhaul" or drive a motor (e.g., cranes, hoists, elevators, inclined conveyors), hysteresis brakes provide smooth, controlled descent or holding torque without the grabbing associated with friction brakes, enhancing safety and control. �⚖️

4. **Torque Limiting u0026 Clutching:** Need a simple, reliable mechanical fuse? A hysteresis brake can be configured as a torque limiter, slipping predictably at a preset torque to protect downstream components from overload. They can also function as smooth-engaging slip clutches. �

5. **Medical u0026 Laboratory Equipment:** Where reliability, quiet operation, and cleanliness are paramount – think centrifuges, analyzers, dialysis machines, precision positioning stages, surgical robots. Hysteresis brakes provide controlled stops, holding force, or tension without particulate generation or noise. ��

6. **Aerospace u0026 Defense:** Critical systems requiring fail-safe operation, high reliability, and resistance to extreme environments often leverage hysteresis technology for applications like antenna positioning, gyro stabilization, and actuator control. ✈️�️

7. **Robotics u0026 Automation:** Joint control, end-effector force feedback, and controlled deceleration in robotic arms benefit from the precise torque control and compactness of hysteresis brakes. �

8. **Exercise Equipment:** Providing smooth, adjustable resistance for treadmills, ellipticals, and stationary bikes, enhancing the user experience without wear-related degradation. �♀️�♂️

**Demystifying the Specs: What to Look For ��**

Not all hysteresis brakes are created equal. Understanding key specifications is crucial for selecting the right solution:

1. **Torque Range:** The maximum continuous torque the brake can deliver. Ensure your application's peak torque requirement falls comfortably within this range, considering any safety factors. Think continuous load, not just peak spikes.

2. **Torque Control Linearity:** How accurately does the output torque follow the input current signal? Look for servo press machine for the most precise control.

3. **Maximum Speed (RPM):** The highest rotational speed the rotor can safely withstand. Exceeding this can lead to catastrophic failure due to centrifugal forces.

4. **Inertia:** The rotor's moment of inertia. A lower inertia means the brake itself has less impact on the system's acceleration/deceleration dynamics, crucial for highly dynamic applications. ↔️

5. **Power Requirements:** Voltage and current needed to generate the rated torque. Ensure your power supply and control circuitry can deliver the required current without excessive voltage drop.

6. **Cooling Method:** How is heat dissipated?

* **Air-Cooled:** Relies on convection and airflow around the brake. Simpler, but limits continuous torque at high duty cycles.

* **Water-Cooled:** Uses circulating coolant (usually water/glycol) through passages in the stator. Allows for significantly higher continuous torque and duty cycles, essential for demanding applications like dynamometers. �

7. **Response Time:** How quickly the brake achieves the commanded torque after a current change. Important for highly dynamic control loops. Milliseconds matter in some contexts.

8. **Construction u0026 Environmentals:** Consider IP rating (ingress protection), operating temperature range, and mounting options to ensure suitability for your environment. �❄️�

**Integration and Control: Making the Magic Work �️�**

The beauty lies in the simplicity of control. Hysteresis brakes typically require a DC power source and a means to control the current:

1. **Simple Voltage Control:** Applying a fixed DC voltage generates a fixed torque. Limited adjustability.

2. **Manual Current Regulation:** Using a variable resistor or potentiometer in series with the brake allows rough torque adjustment. Low cost, low precision.

3. **Precision Current Controller:** This is the gold standard for demanding applications. These electronic controllers take a low-power command signal (e.g., 0-5V, 0-10V, 4-20mA) and amplify it to deliver the *exact* required current to the brake coil, ensuring precise, linear torque control regardless of coil resistance changes (e.g., due to temperature). They often include features like torque ramping, limits, and status monitoring. Look for controllers specifically designed for inductive loads like brake coils.

**Addressing the Murmurs: Common Concerns Debunked �❌**

* **"But they consume power continuously!"** Yes, to generate torque, current must flow. However, weigh this against the *massive* savings from eliminated mechanical wear, reduced downtime, and zero consumables (pads, discs). For tension control applications, the power draw is often only needed during unwind or when actively controlling tension. The TCO math usually favours hysteresis significantly. �➗

* **"Torque drops at high speeds!"** While there is a slight decrease due to eddy current effects in the rotor material at very high speeds, modern high-performance hysteresis alloys minimize this. Crucially, the torque remains *consistent* at any given speed and current, unlike friction brakes which become erratic. For most applications, the decrease is negligible or easily compensated for in the control loop.

* **"They are expensive upfront!"** The initial unit cost might be higher than a basic friction brake. But this is classic false economy. When you factor in the lifespan (often decades), zero maintenance costs, zero replacement parts, eliminated downtime for brake changes, consistent performance, and reliability, the hysteresis brake almost always wins the total cost of ownership race handily. Invest once, benefit forever.

**The Future is Frictionless: Why Now is the Time ⏳�**

The industrial landscape is demanding more: more precision, more reliability, more uptime, more sustainability (less waste!), more intelligent automation. Hysteresis brake technology is not just keeping pace; it's enabling this progress.

* **Smart Factories:** Integrate hysteresis brakes with PLCs and sensors via precision controllers for closed-loop tension control, predictive maintenance (though they rarely fail!), and seamless data integration into Industry 4.0 ecosystems.

* **Advanced Materials:** Development of novel magnetic alloys continues, pushing the boundaries of torque density, speed capability, and temperature stability.

* **Sustainability:** Zero particulate emissions (brake dust), reduced energy consumption compared to fighting friction losses in some systems, and indefinite lifespan all contribute to greener manufacturing. �

* **Miniaturization:** Compact hysteresis solutions are enabling precise control in ever-smaller devices, from medical instruments to micro-robotics.

**Conclusion: Embrace the Silent Revolution �➡️�**

The era of screeching, grinding, high-maintenance friction brakes holding back your productivity and profitability is over. Hysteresis brake technology offers a superior paradigm: silent, precise, reliable, and maintenance-free control. It's not just a component; it's an investment in smoother operations, lower costs, higher quality, and peace of mind.

Whether you're battling tension inconsistencies on a printing press, seeking ultra-smooth control in a medical device, demanding reliability in aerospace, or simply tired of replacing worn brake pads, the solution is powered by an unseen magnetic force.

Don't let your machines be held back by outdated technology. Discover the frictionless future. Explore the precision and reliability of hysteresis brakes. Let the silent force work for you. ✨

(Research hysteresis brake solutions for your specific application. Consult with experts to unlock the potential of frictionless, precision control. Your machines, your bottom line, and your sanity will thank you.) �