The Silent Revolution How Hysteresis Brake Dynamometers Are Transforming Precision Testing �

Author : Kiilerich Huber | Published On : 17 Nov 2025

The relentless hum of machinery, the faint smell of ozone, the intricate dance of data streams – for decades, the world of dynamometer testing was dominated by the familiar presence of eddy current and water brake systems. They got the job done, but often at a cost: noise that drowned out thought, vibration that masked subtle signals, and inherent limitations in control precision. Enter an unsung hero, a technology operating on elegant physics rather than brute force, poised to redefine accuracy and efficiency: the Hysteresis Brake Dynamometer. This isn't just an upgrade; it's a paradigm shift, bringing near-silent operation, exquisite control, and unparalleled reliability to demanding testing environments.

For engineers pushing the boundaries of electric motors, transmissions, gearboxes, and countless other rotating devices, accurate and reliable load simulation isn't just desirable; it's absolutely critical. Your prototypes represent countless hours of design, significant investment, and the future success of your products. The dynamometer is the crucible where theories meet reality, where performance is quantified, weaknesses are exposed, and durability is proven. Choosing the right dynamometer technology isn't a mere procurement decision; it's a strategic investment in the quality, speed, and success of your entire development cycle.

So, what makes Hysteresis Brake Dynamometers stand out in this critical role? The answer lies in the fundamental physics of magnetism and a phenomenon known as hysteresis loss.

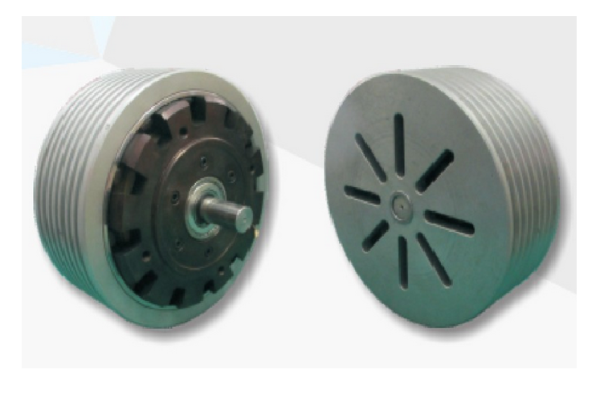

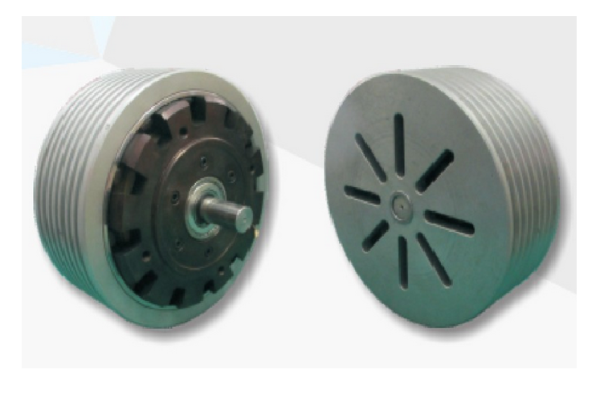

Imagine this: Instead of clamping friction material onto a spinning shaft or inducing eddy currents in a metal disc, the hysteresis brake uses a magnetic field. At its heart are two key components: a smooth rotor made from a special magnetically "hard" material (like cobalt steel alloys) and a stator containing electromagnetic poles. When current flows through the stator windings, it generates a powerful, uniform magnetic field. As the rotor spins within this field, the magnetic domains within the rotor material constantly flip, aligning and realigning with the changing field polarity. This continuous magnetic friction – this internal struggle within the material itself – is the hysteresis loss. It's this energy dissipation that creates the braking torque.

No physical contact. No chattering pads or discs. No turbulent water flow. Just pure, smooth magnetic resistance. This core principle unlocks a cascade of advantages that address the very pain points engineers face daily.

The most immediate benefit? Profoundly quiet operation �️�. Unlike the often-deafening roar of eddy current brakes or the sloshing and pumping noises of water brakes, a hysteresis brake dynamometer operates with a barely perceptible hum, even under full load. This dramatically improves the working environment, reducing fatigue and making communication easier. Crucially, it allows engineers to actually hear the Device Under Test (DUT). Being able to detect subtle bearing whines, gear meshing irregularities, or unexpected resonances during a test – sounds that would be completely masked by a noisy dynamometer – is invaluable for diagnostics and quality assurance. Imagine identifying a potential gearbox issue purely by an unusual sound during a durability run, something impossible with a roaring eddy current brake. That’s the power of silence.

Beyond the auditory benefits lies the realm of exquisite control �. Hysteresis brakes offer an exceptionally wide and linear torque range relative to their input current. servo press is inherent to the hysteresis loss mechanism itself. Torque is directly proportional to the strength of the magnetic field generated by the stator current. Double the current, you essentially double the torque – a beautifully simple and predictable relationship. This translates directly into:

Superior Stability: Holding a torque setpoint with minimal ripple or hunting is crucial for steady-state efficiency mapping or simulating constant road loads. Hysteresis brakes excel here, providing rock-solid stability. Think of calibrating the peak efficiency point of an electric motor; even minor torque fluctuations can skew the results. Hysteresis stability ensures pinpoint accuracy.

Precise Repeatability: Test results are only meaningful if they can be reliably reproduced. The inherent linearity and stable control characteristics of hysteresis brakes ensure that the same input commands consistently yield the same torque outputs, test after test, day after day. This builds confidence in your data.

Smooth Transients: Simulating real-world scenarios often requires rapid changes in load – accelerating up a hill, regenerative braking, shifting gears. Hysteresis brakes respond incredibly quickly to control signal changes. Because the torque is generated magnetically without the inertia of moving mechanical components (like friction pads or water vanes), they can achieve remarkably fast torque rise and fall times. This allows for highly dynamic testing profiles that accurately replicate demanding operational conditions. Simulating the aggressive regenerative braking of an electric vehicle feels authentic and controlled.

But wait, there's more! The magic of "no physical contact" delivers another massive advantage: virtually zero wear and tear �. Since the rotor spins freely within the magnetic field, there’s no friction material to degrade, erode, or generate heat-inducing particulate matter. Water brakes don't have friction wear but suffer from water chemistry issues, corrosion, and potential seal degradation. Eddy current brakes can see disc wear over time under harsh conditions. The hysteresis brake? Its core torque-generating mechanism is non-contact and non-consumptive. This translates directly into:

Exceptional Longevity: Hysteresis brake dynamometers are renowned for their longevity and minimal maintenance requirements. There are no brushes to replace (like some DC machines), no friction pads to service, no water to treat and filter, and no complex hydraulic systems. The primary maintenance might involve periodic bearing checks and ensuring clean cooling air paths – a significant reduction in downtime and operational cost.

Consistent Performance Over Time: Without wear components degrading, the torque output and control characteristics remain remarkably consistent throughout the dynamometer's lifespan. You don't get the gradual performance drift associated with wearing friction materials or deteriorating water brake components. Your calibration stays true longer.

Clean Operation: The absence of wear debris (dust from friction materials, water spray mist, or potential oil leaks from hydraulic systems) means a cleaner test environment. This is particularly crucial for testing sensitive components like electric motors or electronics where contamination could affect results or damage the DUT.

Heat management is always a challenge in dynamometer operation. While hysteresis brakes generate heat through the magnetic hysteresis losses in the rotor, the design is optimized for efficient cooling. Rotors are typically designed with high thermal conductivity and often incorporate forced-air cooling channels. The smooth, solid rotor design provides an excellent surface for heat dissipation. Modern designs efficiently manage this heat, ensuring stable operation even during extended high-torque test cycles. The lack of friction-generated heat (a massive source in mechanical brakes) is also a significant benefit.

Where does this unique combination of silence, precision, stability, and durability shine brightest? The applications are diverse and critical:

Electric Motor and Drive Testing: This is perhaps the sweet spot. Hysteresis brakes are ideal for mapping motor efficiency (requiring extreme torque stability at low speeds), testing dynamic performance (fast acceleration/regeneration), evaluating controller responses, and conducting endurance tests. The silent operation allows engineers to hear motor whine, bearing noise, and potential winding issues. The precise control is vital for accurately characterizing torque ripple and developing sophisticated motor control algorithms. Whether it's a tiny drone motor or a massive traction motor for an electric bus, hysteresis provides the fidelity needed.

Gearbox and Transmission Testing: Evaluating gear meshing efficiency, noise vibration and harshness (NVH), shift quality, and durability demands smooth, controllable loading. The ability of hysteresis brakes to hold torque steadily at very low speeds (even down to zero speed!) is essential for testing static breakaway torque or low-speed creep characteristics in transmissions. Their fast response accurately simulates the sudden load changes experienced during gear shifts. The quiet operation is paramount for precise acoustic analysis of gear whine or rattle.

Small Engine Testing (Generators, Tools, Lawn Equipment): Testing small internal combustion engines for performance, fuel efficiency, emissions (during steady-state mapping), and durability benefits significantly from the smooth control, stability, and quiet operation of hysteresis dynamometers. Their compact size relative to their torque capability is also advantageous.

Component Testing: Bearings, couplings, clutches, and other rotational components subjected to precise and repeatable loading conditions thrive under hysteresis control. The ability to apply smooth torque without vibrational inputs provides cleaner, more reliable fatigue data.

Aerospace Actuators and Auxiliary Power Units (APUs): Testing critical flight components demands utmost reliability and precision. Hysteresis brakes provide the accurate, stable, and vibration-free loading needed for qualifying these high-stakes systems.

University Research and Development Labs: The combination of safety (cool operation, no high-pressure water, no hydraulic fluid), quietness, precision, and relatively low maintenance makes hysteresis dynamometers a popular and practical choice for academic settings where flexibility and reliability are key.

Of course, no technology is without considerations. Hysteresis brakes typically have a higher initial cost compared to basic eddy current or water brakes. However, this must be evaluated against the Total Cost of Ownership (TCO). Factor in the drastically reduced maintenance costs (no consumables, minimal downtime), exceptional longevity, energy efficiency (especially compared to water brakes requiring constant pumping), and the value of superior data quality and faster test times enabled by precise control. Often, the payback period is surprisingly short for high-utilization applications. Furthermore, while peak power dissipation capabilities can be very high, continuous dissipation at maximum torque requires robust cooling solutions, though modern designs handle this effectively. They are generally not the go-to for applications requiring the *absolute highest* continuous power dissipation in a minimal footprint compared to massive water brakes, but they excel in the precision and control domains.

Implementing a hysteresis brake dynamometer system involves more than just the brake itself. A sophisticated controller is essential. This controller translates the desired torque (or speed) profile into the precise current required by the stator windings. Modern digital controllers offer advanced features:

Closed-Loop Control: Precisely regulates torque or speed based on feedback from high-accuracy transducers.

Complex Profile Generation: Ability to run sophisticated test sequences simulating real-world driving cycles, step changes, ramps, and sine waves.

Data Acquisition Integration: Seamless recording of torque, speed, temperature, voltage, current, and other critical parameters from both the dynamometer and the DUT.

Safety Systems: Overspeed protection, overtorque limits, temperature monitoring, and emergency stops.

User Interface: Intuitive software for test setup, execution, monitoring, and data analysis.

Choosing a system with a powerful, user-friendly controller is paramount to unlocking the full potential of the hysteresis brake technology.

The future of hysteresis brake dynamometers is intertwined with the electrification revolution and the increasing demand for precision. As electric motors become more sophisticated, requiring finer control and more detailed NVH analysis, the strengths of hysteresis become even more critical. Advancements in magnetic materials, cooling techniques, and control algorithms continue to push the boundaries of torque density, speed range, and dynamic response. Integration with AI for predictive testing and autonomous test sequence optimization is on the horizon.

In conclusion, the Hysteresis Brake Dynamometer represents a sophisticated leap forward in testing technology. It moves beyond the limitations of friction and fluid dynamics, harnessing the elegant physics of magnetism to deliver unparalleled levels of quietness, control precision, stability, and reliability. For engineers and researchers who demand the highest quality data, who need to hear their devices, who require repeatable results over years of operation, and who value minimal operational headaches, it’s not just another tool – it’s the silent partner enabling breakthrough innovation. In the high-stakes world of developing and validating rotating machinery, settling for the noisy status quo is no longer an option. The era of magnetic precision has arrived. ��

Is your testing being held back by noise, instability, or maintenance woes? Are you ready to experience the silent revolution in precision loading? The difference isn't just measurable; it's audible. It’s time to talk about how hysteresis brake dynamometry can transform your development process, improve your data quality, and accelerate your path to market. Let's discuss your specific application challenges and explore the possibilities. The future of precision testing is incredibly quiet. ✨