The Quiet Revolution on Your Factory Floor How Servo Press Technology is Reshaping Manufacturing &#

Author : Bjerregaard Lyhne | Published On : 16 Nov 2025

The rhythmic thud… thud… THUD of a mechanical press is a familiar heartbeat in countless factories worldwide. It’s the sound of production, of progress, of metal being shaped into countless essential components. But listen closely. Something new is weaving its way into this industrial symphony. It’s smoother, quieter, infinitely more flexible, and it’s unlocking possibilities once deemed impossible. Welcome to the era of the Servo Press – not just an upgrade, but a fundamental transformation. �

For decades, mechanical and hydraulic presses dominated stamping and forming operations. They got the job done, sure. But their limitations were as inherent as their power: rigid stroke lengths, inflexible slide motion, significant energy waste, noise that demanded ear protection and concrete foundations, and maintenance schedules dictated by wear and tear on clutches, brakes, and hydraulics. Precision, especially for complex or delicate parts, often came at the cost of speed or required extensive secondary operations. Imagine trying to paint a masterpiece with only a roller – possible, perhaps, but lacking the nuance of finer brushes.

**The Servo Difference: Precision Engineered Motion �**

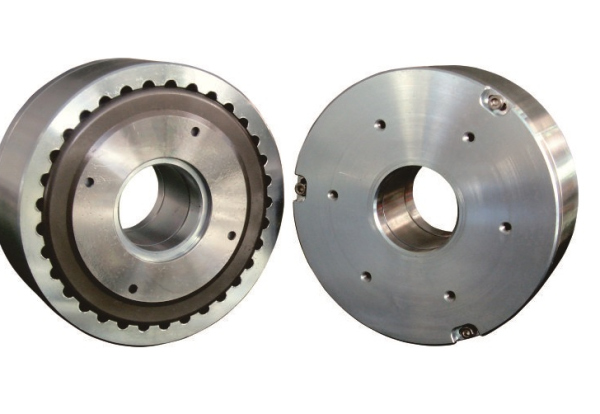

Enter the Servo Press. At its core, the magic lies in replacing the traditional flywheel, clutch/brake, or hydraulic power unit with a powerful, intelligent servo motor directly coupled to the ram (the moving part that delivers the force). This seemingly simple substitution unlocks a universe of control:

1. **Unparalleled Freedom of Motion:** This is the game-changer. Forget fixed strokes dictated by mechanical linkages. A servo press ram can be programmed to move in virtually *any* velocity profile. Need a slow, gentle approach to precisely position material? Done. Require blistering speed through the non-forming parts of the stroke to boost output? Easy. Want a carefully controlled, constant velocity during the actual forming process to ensure perfect material flow and minimal springback? Absolutely. Need a specific dwell time at the bottom of the stroke? Program it. Or even a multi-step press operation within a single stroke? The servo press handles it effortlessly. https://www.validynamics.com/servopress/ ’s like giving the press a brain and letting it choreograph the perfect dance for every single part. ��

2. **Pinpoint Precision u0026 Repeatability:** Driven by advanced CNC-style controllers and high-resolution encoders, servo presses achieve micron-level positioning accuracy, stroke after stroke, day after day. This isn't just about hitting a target depth; it’s about controlling the *entire* path with extreme fidelity. This level of control is crucial for:

* **Micro-stamping:** Creating incredibly small, intricate parts (think electronics connectors, medical device components) where even micron-level variations are unacceptable.

* **Eliminating Springback:** By precisely controlling the forming velocity and applying optimal pressure at the bottom of the stroke, material memory (springback) is dramatically reduced, leading to parts that hold their shape right off the press, minimizing scrap and secondary corrections.

* **Coining u0026 Precision Forming:** Achieving net-shape forming with exceptional surface finish and dimensional stability.

3. **Unmatched Flexibility u0026 Quick Changeovers:** Changing a job on a traditional press often meant mechanical adjustments – changing linkages, cams, or hydraulic settings – taking valuable production time offline. With a servo press, a new part program is simply loaded into the controller. Stroke length, motion profile, tonnage monitoring points – it’s all software. Switching from a deep-drawn cup to a shallow embossed panel might take minutes, not hours. This agility is a cornerstone of modern, demand-driven manufacturing.

4. **Silent Power u0026 Reduced Vibration �:** The absence of a constantly spinning flywheel and the engagement/disengagement of a clutch/brake system drastically reduces noise levels. Operators can work more comfortably without constant hearing protection. Furthermore, the smoother, controlled motion generates significantly less vibration, reducing stress on the press frame, the foundation, and surrounding equipment. This also opens doors for integrating presses into cleaner environments or multi-process cells.

5. **Energy Efficiency Champion �:** Traditional presses are energy hogs. Mechanical presses waste massive amounts of energy spinning the flywheel continuously, even when idle. Hydraulics waste energy through heat generation in valves and pumps. Servo presses? They consume power *only when moving the ram*. During pauses or at the top/bottom of the stroke, energy draw is minimal. Regenerative drives can even capture energy during the ram deceleration phase and feed it back to the power grid. The energy savings are substantial, often 30-60% or more compared to conventional presses – a direct boost to the bottom line and sustainability goals.

6. **Enhanced Tool Life u0026 Protection �️:** Precise control means less shock loading on the tooling. The ability to control approach speed prevents slamming into the material. Monitoring servo motor torque (which correlates directly with press tonnage) allows for real-time overload detection. If a misfeed, double blank, or foreign object is detected during the stroke, the press can stop or even reverse the ram *instantly* before catastrophic tool damage occurs. This predictive protection saves thousands, even tens of thousands, in tooling repair or replacement costs.

7. **Optimized Material Utilization:** Precise control over the forming process, especially in deep drawing applications, allows for more aggressive forming limits. This can translate to using thinner gauge materials or achieving deeper draws without tearing, leading to material savings and lighter final products.

8. **Data-Driven Manufacturing �:** Modern servo presses are data hubs. They continuously monitor and record key parameters: ram position, velocity, force (tonnage), energy consumption per stroke, cycle time, and more. This data isn't just for diagnostics; it's gold for process optimization, predictive maintenance, quality assurance traceability, and overall equipment effectiveness (OEE) tracking. See a subtle drift in forming force? Investigate tool wear or material variation before it causes scrap. Identify cycles taking longer than programmed? Pinpoint potential mechanical issues early.

**Beyond Stamping: The Expanding Universe of Servo Press Applications �**

While stamping remains a core application, the versatility of servo motion is driving adoption in numerous other areas:

* **Precision Forging:** Controlled deformation rates lead to superior grain structure, reduced forging loads, and better part integrity.

* **Metal Powder Compaction:** Precise control of compaction speed and dwell time is critical for achieving uniform density and strength in sintered parts.

* **Plastic u0026 Composite Molding/Forming:** Servo presses provide the controlled, repeatable force profiles needed for compression molding, thermoforming, and composite layup/curing processes.

* **Assembly u0026 Joining:** Riveting, staking, bearing insertion, and other press-fit operations benefit immensely from programmable force-displacement profiles, ensuring consistent joint quality without damaging components.

* **Testing u0026 Calibration:** Used as highly controllable force application systems for material testing or calibration of sensors and instruments.

**Addressing the Elephant in the Room: Initial Investment u0026 ROI �**

Yes, servo presses typically command a higher initial purchase price than their traditional counterparts. This is the point where many plant managers historically hesitated. However, viewing this solely through the lens of purchase price is a profound mistake. The true measure is *Total Cost of Ownership (TCO)* and *Return on Investment (ROI)*. Let’s break it down:

* **Energy Savings:** The dramatic reduction in power consumption directly lowers the operating cost per part, paying back the premium year after year.

* **Reduced Scrap u0026 Rework:** Superior process control means fewer defective parts. Eliminating springback issues alone can save massive amounts of scrap and costly secondary operations.

* **Extended Tool Life u0026 Protection:** Avoiding catastrophic die crashes and reducing daily wear through controlled motion drastically lowers tooling maintenance and replacement budgets.

* **Increased Productivity:** Faster cycle times (optimized motion profiles), drastically reduced setup/changeover times, and higher overall equipment effectiveness (OEE) mean more good parts produced per shift.

* **Lower Maintenance Costs:** Fewer mechanical components (no clutch/brake, simplified drive train) translates to less preventative maintenance and fewer breakdowns.

* **Quality Premium:** The ability to produce parts with tighter tolerances, better surface finishes, and complex geometries can open doors to new, higher-margin markets or secure existing contracts demanding superior quality.

* **Floor Space u0026 Facility Savings:** Reduced vibration often means less massive foundations are needed. Quieter operation might allow placement in areas previously unsuitable for presses.

The ROI calculation is compelling. Payback periods often range between 1-3 years, sometimes faster, depending on the application and utilization. Beyond the numbers, there’s the strategic advantage of agility, quality leadership, and future-proofing your manufacturing capabilities.

**Real-World Impact: Servo Presses in Action �**

* **Scenario 1: The Automotive Tier 1 Supplier.** Struggling with springback on complex high-strength steel structural components, leading to inconsistent fit and costly rework. Implementing a servo press allowed precise control of the forming velocity and bottom dwell, virtually eliminating springback. Result: Scrap rates plummeted by 85%, secondary straightening operations were eliminated, and part consistency met stringent OEM requirements flawlessly. The energy savings paid for the press upgrade within 18 months.

* **Scenario 2: The Medical Device Manufacturer.** Needed to produce ultra-precise, miniature titanium components with intricate features. Traditional presses lacked the precision and control, resulting in high scrap and limiting design possibilities. A micro-servo press provided the micron-level accuracy and gentle, programmable touch required. Result: Yield soared, allowing production of previously unfeasible designs, securing lucrative new contracts in a demanding market.

* **Scenario 3: The High-Mix, Low-Volume Job Shop.** Losing bids because long changeover times on their mechanical presses made small batches unprofitable. Installing servo presses reduced changeovers from hours to minutes. Result: They became competitive for smaller orders, increased machine utilization dramatically, and won significant new business based on their speed and flexibility.

**Choosing the Right Servo Press Partner �**

Not all servo presses are created equal. Key considerations include:

* **Drive Technology:** Direct-drive systems offer the highest precision and responsiveness but can be more expensive. Belt-driven systems offer a cost-effective entry point but may have slightly less dynamic response. Understand the trade-offs for your needs.

* **Control System u0026 Software:** The brain of the press. Look for an intuitive, powerful HMI (Human Machine Interface), robust programming capabilities for complex motion profiles, advanced tonnage monitoring and protection features, and seamless data integration capabilities (OPC UA, MTConnect, etc.). Ease of programming is crucial for operators.

* **Frame Rigidity u0026 Construction:** Even with smoother motion, the frame must withstand the forming forces without deflection. Look for robust, well-designed frames using high-quality materials and advanced engineering (FEA-optimized).

* **Service u0026 Support:** This is critical technology. Choose a manufacturer with a proven track record, readily available parts, and highly trained service technicians. Ask about remote diagnostics capabilities. Local support presence is a major plus.

* **Application Expertise:** Work with a partner who understands *your* specific forming challenges and can recommend not just a press, but the right configuration, tooling considerations, and optimal motion profiles for your parts.

**The Future is Servo-Controlled �**

The trajectory is clear. As demands for higher quality, greater efficiency, increased flexibility, and sustainable manufacturing intensify, servo press technology moves from being a premium option to the standard for competitive manufacturing. The advancements continue:

* **AI Integration:** Using machine learning to analyze press data in real-time, predicting tool wear, optimizing motion profiles automatically, and identifying subtle process deviations before they cause defects.

* **Enhanced Connectivity:** Seamless integration with factory-wide MES (Manufacturing Execution Systems) and ERP platforms for true end-to-end digital production control.

* **Hybrid Solutions:** Combining servo flexibility with other technologies for specific applications requiring unique force profiles.

* **Broader Tonnage Ranges:** Servo technology is becoming viable for increasingly larger press applications.

**Is it Time for Your Revolution? �**

That familiar thud may represent your past, but it doesn't have to define your future. The servo press represents more than just a machine; it represents a fundamental shift towards smarter, more responsive, and more profitable manufacturing. It’s about producing parts you couldn't before, with quality levels that delight customers, at speeds that outpace competitors, while consuming less energy and preserving your valuable tooling.

If you're wrestling with scrap rates, struggling with complex part geometries, facing pressure for shorter runs and quicker changeovers, or simply looking to slash your energy bills and boost your sustainability credentials, the servo press deserves your serious consideration. It’s not just an investment in equipment; it’s an investment in the future resilience and competitiveness of your entire manufacturing operation.

The quiet revolution is happening. The question is, will you be leading it from the front, or playing catch-up from behind? Explore the possibilities. Talk to experts. Witness the technology in action. The precision, the flexibility, the efficiency – it’s transforming factories one perfect stroke at a time. Your next breakthrough part might be just one programmable motion profile away. ✨

Ready to experience the servo advantage? Contact our team of experts today for a personalized consultation and discover how this transformative technology can revolutionize *your* production floor. Let's build the future, precisely.