SRJ Heatt: Your Trusted Source for Fischer PHE Gaskets & Plates

Author : SRJ Heatt | Published On : 17 Nov 2025

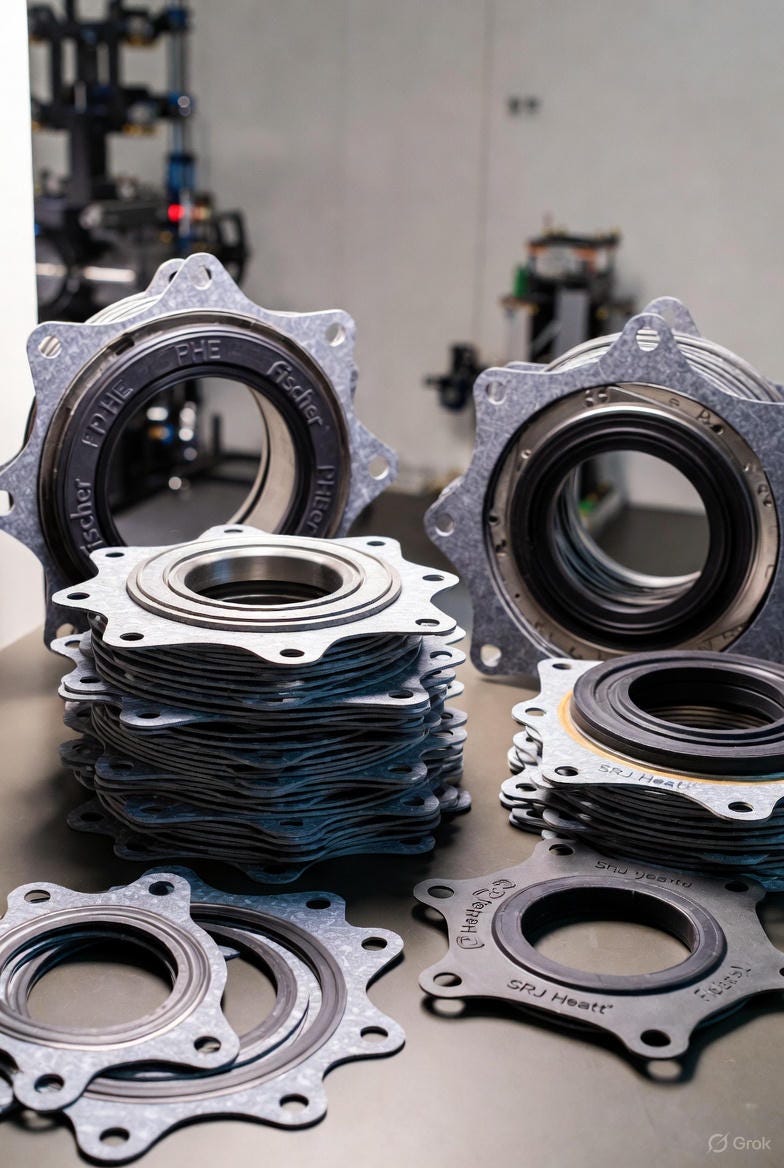

In the world of industrial heat transfer, Fischer PHE gaskets & plates stand out as essential components for maintaining efficient plate heat exchangers. Whether you’re managing a food processing plant, chemical facility, or HVAC system, the reliability of your PHE replacement parts directly impacts operational efficiency and downtime costs. At SRJ Heatt, we specialize in delivering premium Fischer gasketed plate heat exchanger solutions that meet the highest industry standards.

Understanding Fischer PHE Gaskets & Plates

Fischer PHE gaskets & plates form the core of any gasketed plate heat exchanger system. The heat exchanger plates are precision-engineered to maximize surface area while minimizing pressure drop, ensuring optimal heat transfer efficiency. Meanwhile, PHE gaskets create secure seals between plates, preventing cross-contamination and leakage under high-pressure conditions.

The innovative design of Fischer plate heat exchangers incorporates advanced plate patterns that enhance turbulence and improve thermal performance. This results in superior heat recovery capabilities compared to traditional shell-and-tube heat exchangers. When properly maintained with quality SRJ Heatt Fischer PHE gaskets & plates, these systems can achieve up to 95% heat transfer efficiency.

Why Choose SRJ Heatt for Fischer PHE Gaskets & Plates

At SRJ Heatt, we understand that every industrial heat exchanger application has unique requirements. Our extensive inventory of Fischer-compatible gaskets and replacement plates ensures you receive components that match OEM specifications exactly. Each PHE gasket material is carefully selected based on your operating temperature, pressure, and media compatibility needs.

Our Fischer PHE gaskets & plates undergo rigorous quality testing to guarantee:

- Perfect fit with existing plate pack configurations

- Resistance to thermal cycling and chemical degradation

- Extended service life for reduced maintenance costs

- Compliance with FDA and 3A standards for food-grade applications

Common Applications for Fischer PHE Gaskets & Plates

The versatility of Fischer plate heat exchangers makes them ideal for numerous industries. In dairy processing, SRJ Heatt Fischer PHE gaskets & plates maintain sanitary conditions during pasteurization. Chemical plants rely on our corrosion-resistant heat exchanger gaskets to handle aggressive fluids safely.

Power generation facilities use our PHE replacement parts for efficient district heating systems, while pharmaceutical manufacturers trust SRJ Heatt for validated clean-in-place compatible solutions. The robust construction of Fischer gasketed plate heat exchangers ensures reliable performance even in demanding environments.

Maintenance Tips for Fischer PHE Gaskets & Plates

Proper care extends the lifespan of your Fischer PHE gaskets & plates. Regular inspection of plate heat exchanger gaskets for wear patterns helps prevent unexpected failures. SRJ Heatt recommends following these maintenance practices:

- Monitor differential pressure across the plate pack

- Perform chemical cleaning using approved CIP solutions

- Replace PHE gaskets during scheduled shutdowns

- Store spare replacement plates in climate-controlled conditions

- Document heat exchanger performance metrics regularly

Signs You Need Fischer PHE Gaskets & Plates Replacement

Recognizing when to replace Fischer PHE gaskets & plates prevents costly emergencies. Key indicators include:

- Increased pressure drop across the heat exchanger

- Visible leakage around plate edges

- Reduced heat transfer efficiency

- Corrosion on heat exchanger plates

- Gasket hardening or cracking

SRJ Heatt maintains ready stock of all popular Fischer model gaskets and plates, ensuring minimal downtime during emergency replacements.

Technical Specifications of Fischer PHE Gaskets & Plates

Our SRJ Heatt Fischer PHE gaskets & plates feature advanced materials engineered for specific applications:

ComponentMaterial OptionsTemperature RangePressure RatingPHE GasketsNBR, EPDM, Viton, HNBR-40°C to 180°CUp to 25 barHeat Exchanger PlatesSS316, Titanium, Hastelloy-50°C to 350°CUp to 30 bar

These Fischer-compatible parts maintain dimensional accuracy within 0.1mm tolerance, ensuring perfect alignment in your plate heat exchanger frame.

The SRJ Heatt Advantage in Fischer PHE Solutions

Choosing SRJ Heatt for your Fischer PHE gaskets & plates means partnering with experts who understand gasketed plate heat exchanger technology inside out. Our technical team provides comprehensive support from plate heat exchanger selection through installation and maintenance.

We offer customized PHE spare parts kits that include everything needed for complete plate pack refurbishment. This eliminates the hassle of sourcing individual Fischer gasket sets or replacement plates separately.

Future-Proof Your Heat Transfer Systems

The landscape of industrial heat exchangers continues evolving, with increasing demands for energy efficiency and sustainability. SRJ Heatt stays ahead by developing next-generation Fischer PHE gaskets & plates that incorporate advanced polymers and surface treatments.

Our R&D team works closely with plate heat exchanger manufacturers to create solutions that reduce environmental impact while maintaining superior performance. Whether you need high-temperature gaskets or ultra-clean plates for pharmaceutical applications, SRJ Heatt delivers.

Conclusion: Trust SRJ Heatt for Fischer PHE Excellence

When reliability matters, Fischer PHE gaskets & plates from SRJ Heatt provide the perfect combination of quality, availability, and technical expertise. Our commitment to customer success ensures your gasketed plate heat exchanger operates at peak efficiency year after year.

Don’t compromise on heat exchanger performance. Contact SRJ Heatt today for all your Fischer-compatible gaskets, PHE replacement parts, and complete plate heat exchanger solutions. Experience the difference that genuine expertise makes in maintaining your critical heat transfer equipment.