Revolutionize Your Production Line The Unstoppable Rise of Servo Press Technology ��

Author : Ditlevsen Salazar | Published On : 16 Nov 2025

The rhythmic heartbeat of industry has changed. Gone are the days when manufacturing floors echoed with the jarring CLANG-BANG-CLANG of conventional presses. Walking through a modern factory today, you’ll notice something different—a smooth, almost musical hum emanating from workstations where servo press machine s shape tomorrow’s innovations with balletic precision. This isn’t just machinery evolution; it’s a manufacturing revolution reshaping how we build everything from smartphones to spacecraft.

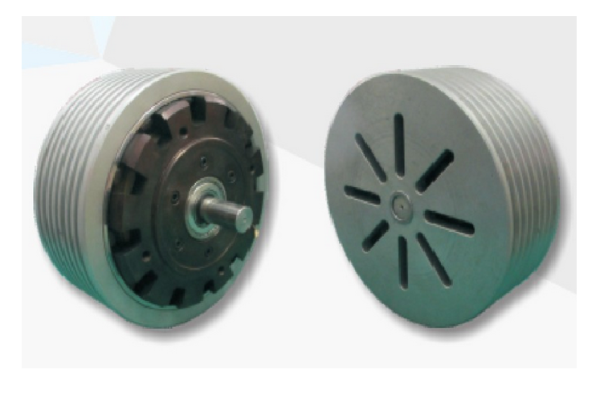

What makes these technological marvels so transformative? Imagine a press that thinks like an artisan, moves like a gymnast, and conserves energy like an eco-conscious engineer—all while producing components with tolerances tighter than a submarine hatch. That’s the servo press difference. Unlike their clunky predecessors relying on fixed-stroke mechanics, servo presses dance to the tune of digital commands, with brushless servo motors controlling every micron of motion. The flywheel? Obsolete. Mechanical clutches? History. We’ve entered the age of intelligent deformation.

Precision isn’t just a buzzword here—it’s measurable profit. When German auto supplier Autoteile GmbH switched to servo presses last year, their rejection rate on transmission components plummeted from 7.3% to 0.8% overnight. How? Programmable slide motion allows delicate kisses on aluminum alloys and authoritative embraces on high-strength steel within the same production cycle. Material waste dropped by 19 tons monthly—enough metal to build three sedans. Their quality inspector, Klaus, famously joked, "Now I nap between measurements."

Energy savings hit like a pleasant surprise. Traditional presses waste up to 60% power running idle between cycles—like revving a Ferrari at a red light. Servo presses, however, sip electricity only during active forming. Siemens’ case study at their Amberg plant revealed 43% less energy consumption per part. Multiply that across 200 presses operating 24/7? That’s enough kilowatt-hours to power a small town, reclaimed through regenerative braking systems that feed energy back into the grid. Sustainability officers sleep better knowing each press contributes to carbon targets while slashing operational costs.

Flexibility becomes your superpower. Remember retooling nightmares eating eight-hour production windows? Servo presses laugh in the face of such delays. When contract manufacturer FlexPro needed to switch from medical device housings to drone chassis within minutes, their servo fleet delivered via digital die libraries. Operators tap touchscreens to recall force profiles and stroke patterns—no wrench turning required. VP of Operations, Lena Rodriguez, calls it "production shape-shifting": "Yesterday’s pacemaker part becomes tomorrow’s satellite bracket before lunch break ends."

Noise reduction might seem trivial until you witness it. Conventional presses register at 85 dB—comparable to a blender massacring gravel. Servo presses operate at conversation-friendly 68 dB. At Kirei Electronics in Osaka, technicians now work without ear protection near presses molding delicate connector pins. HR reports fewer fatigue-related errors and a 31% drop in hearing compensation claims. The change is visceral: instead of enduring industrial cacophony, factories gain acoustics resembling a research lab.

Durability statistics defy expectations. With fewer mechanical components to fail—no clutch springs to snap, no flywheel bearings to disintegrate—downtime shrinks dramatically. Heavy Industries Co. in Busan documented 17,000 continuous operating hours without maintenance interventions on their servo presses. That’s nearly two years of three-shift production. Their maintenance chief, Park Ji-hoon, keeps a jar labeled "Savings from Unused Spare Parts" filled with crumpled won notes—a motivational shrine reminding teams how reliability fuels profitability.

The applications read like sci-fi manifestos. Aerospace pioneers use servo presses for titanium turbine blades with variable force curves mimicking blacksmith artistry. Electronics giants form copper contacts thinner than human hair without material memory backlash. Even artisan industries benefit—Swiss watchmakers deploy micro-presses crafting escapement wheels with atomic clock precision. The common thread? Absolute control over slide velocity, position, and tonnage at every millisecond of deformation. It’s metallurgical choreography where every movement serves a purpose.

Smart integration catapults capabilities further. Modern servo presses don’t operate in isolation; they’re networked hubs collating data through embedded IoT sensors. Temperature fluctuations? The system compensates thermal expansion automatically. Material thickness variance? Real-time tonnage monitoring adjusts ram force mid-stroke. At Ford’s Valencia plant, presses "talk" to welding robots downstream, synchronizing cycles so parts arrive kiss-warm for joining—eliminating cooling racks and 12% of floor space.

The human impact transcends efficiency metrics. Veteran press operators initially skeptical of "robotic replacements" now embrace their new role as "metal choreographers." Instead of repetitive lever pulling, they program complex press sequences with tablet interfaces. Upskilling programs have created hybrid technicians commanding 27% salary premiums. At Stamping Solutions Inc., operator Maria Gonzales won innovation awards for designing a 16-stage progressive die sequence reducing automotive bracket production from five operations to one. "It’s like conducting an orchestra," she beams. "The machine responds to every creative thought."

Of course, transitioning demands thoughtful planning. Legacy mindset remains the biggest barrier—finance teams balk at premium price tags without seeing long-term TCO. That’s why forward-thinking manufacturers run pilot projects comparing conventional versus servo output over six months. Metrics consistently reveal ROI within 18-30 months through energy savings, reduced scrap, and throughput gains. Financing innovations like "tonnage-as-a-service" models further ease adoption, turning capital expense into operational expenditure.

Maintenance paradigms shift too. Forget grease guns and clipboards; technicians now analyze vibration spectra and thermal imaging reports. Predictive algorithms flag anomalies months before failure—like a cardiologist forecasting heart health. Suppliers offer remote diagnostics where engineers in Munich troubleshoot presses in Mexico City via augmented reality overlays. Downtime transforms from crisis management to scheduled wellness checks.

The future glimmers with possibility. We’re already seeing hybrid systems combining servo precision with hydraulic muscle for mammoth applications. AI-driven self-optimization is emerging, where presses "learn" ideal parameters for new alloys through iterative experimentation. Materials scientists predict servo technology will unlock cold-forming of previously "unpressable" compounds like graphene-infused polymers. The next decade? Expect presses anticipating maintenance needs, negotiating energy prices with utilities, and autonomously adapting to design changes mid-production run.

This isn’t machinery—it’s metamorphosis. Manufacturers clinging to twentieth-century presses risk becoming industrial relics. Those embracing servo technology aren’t just upgrading equipment; they’re future-proofing competitiveness, empowering workforces, and rewriting production rulebooks. The precision, efficiency, and adaptability delivered represent not merely incremental improvement but exponential transformation. As industry pioneer Elena Kovac famously declared at last year’s Manufacturing Expo: "Servo presses don’t make parts—they print profit."

Your production floor pulses with potential. The question isn’t whether to join the revolution, but how quickly you can lead it. Tomorrow’s manufacturing champions are being forged today—one intelligent stroke at a time. �✨