Precision Unleashed How Servo Control Systems Power Your World ⚙️⚡️ᖟ

Author : Castillo Dalsgaard | Published On : 04 Nov 2025

Imagine this: a robotic arm, moving with balletic grace, welding a seam thinner than a human hair on a car chassis. Picture a high-speed packaging line, where bottles zip past, filled to the exact milliliter, capped, and labeled in a blur of perfect synchronization. Envision a delicate surgical device, guided by a surgeon's steady hand via remote control, performing intricate maneuvers deep inside the human body with zero tremor. What invisible maestro conducts this symphony of precision? The answer lies deep within the machine, humming with focused energy: the **Servo Control System**. ��

Forget clunky, imprecise movements. Forget motors that simply spin when told to go. Servo systems are the brain and the brawn of modern automation. They are the difference between a rough sketch and a photorealistic masterpiece, between brute force and elegant accuracy. They are the silent engines driving innovation across countless industries, making the impossible routine and the complex achievable. If your operations demand pinpoint accuracy, blistering speed, relentless consistency, and adaptable intelligence, understanding the power of the servo is not just beneficial—it's essential.

**The Core Principle: Closing the Loop ��**

Unlike a simple motor that receives an "on" switch and spins wildly until told to stop, a servo system operates on a fundamental principle called **closed-loop feedback control**. Think of it like constantly having a conversation:

1. **Command:** You tell the system *exactly* where you want an object to be, how fast it should move, and how forcefully it should push or pull. This is the "setpoint."

2. **Action:** The servo motor (the muscle) starts moving, trying to reach that desired position, speed, or torque.

3. **Sensing:** Crucially, the system *doesn't trust blind action*. Sensors (like encoders, resolvers, or tachometers – the eyes and ears) constantly monitor the *actual* position, speed, or torque being achieved.

4. **Comparison u0026 Correction:** The system's electronic controller (the brain) instantly compares the *actual* measurement with the *commanded* setpoint.

5. **Adjustment:** If there's any difference (an "error"), the controller swiftly calculates the necessary correction. It sends a precise signal to adjust the motor's power, direction, or braking.

6. **Repeat:** This cycle – command, sense, compare, correct – happens thousands, even millions, of times per second.

This relentless feedback loop is the magic. It allows the servo system to instantly react to disturbances – friction, changing loads, vibrations, inertia – anything trying to push it off course. It self-corrects continuously, ensuring the final motion matches the command with astonishing fidelity.

**Why Servo Control Reigns Supreme: Beyond Brute Force �**

This closed-loop architecture unlocks capabilities that define modern precision machinery:

1. **Pinpoint Accuracy u0026 Precision: �** This is the crown jewel. Servo systems can position components down to fractions of a micron (one-millionth of a meter). Think semiconductor manufacturing placing microscopic circuits, or laser cutting machines etching intricate patterns. Repetitive accuracy ensures every single product is identical, crucial for quality control.

2. **Lightning-Fast Response u0026 High Speed: ⚡️⏩** Servo motors accelerate and decelerate incredibly quickly. They can reach high speeds and change direction almost instantaneously. This is vital for pick-and-place robots on fast assembly lines, CNC machines cutting complex shapes efficiently, or high-speed printing presses.

3. **Dynamic Torque Control: ��** Servo systems precisely control force (torque). They can deliver smooth, constant force regardless of speed changes or load variations. This is essential for applications like tension control in winding webs (plastic, film, textiles), pressing operations requiring consistent pressure, or robotic arms handling delicate objects without crushing them.

4. **Unwavering Stability u0026 Smoothness: �➡️�** The constant feedback minimizes oscillations and vibrations. Motion is smooth, predictable, and stable, even under challenging conditions. This reduces wear and tear on machinery, prevents product damage, and ensures smoother operation (think camera gimbals for silky footage).

5. **Energy Efficiency u0026 Optimized Performance: ��** By delivering *only* the power needed at any precise moment, and utilizing regenerative braking (converting kinetic energy during deceleration back into electricity), modern servo systems are significantly more energy-efficient than older technologies. This saves costs and supports sustainability goals.

6. **Adaptability u0026 Intelligence: ��** Advanced servo drives and controllers are incredibly programmable. Motion profiles (position, speed, acceleration curves) can be easily customized on the fly for different tasks. They integrate seamlessly with higher-level automation systems (PLCs, HMIs, SCADA) and increasingly incorporate smart features like predictive maintenance diagnostics and machine learning optimization.

7. **Scalability u0026 Modularity: ��** Servo components (drives, motors, feedback devices) come in a vast range of sizes and power ratings, from miniature motors driving tiny medical instruments to massive units powering industrial presses or ship rudders. They can be configured into complex multi-axis systems for robotic arms or CNC machines.

**Where Servo Systems Shape Our Reality: From Factory Floors to Operating Rooms �⚕️��**

The applications of servo control are breathtakingly diverse, touching almost every aspect of modern life:

* **Industrial Automation u0026 Robotics: ��**

* **Robotics:** Articulated arms for welding, painting, assembly, palletizing, material handling. Precise joint control enables complex motion.

* **CNC Machining:** Milling, turning, laser cutting, waterjet cutting. Controlling the precise movement of cutting tools across multiple axes.

* **Packaging u0026 Filling:** Form-fill-seal machines, bottle fillers, cappers, labelers. High-speed, accurate positioning of containers, filling valves, and labels.

* **Printing: �️** Controlling paper feed, roller pressure, print head positioning for high-resolution output at high speeds.

* **Textiles u0026 Web Handling:** Precision control of tension in winding, unwinding, coating, and slitting processes.

* **Assembly Lines:** Screwdriving, pressing, insertion, testing stations requiring precise force and positioning.

* **Semiconductor Manufacturing: ��** Photolithography steppers, wafer handlers, wire bonding. Operating at nanometer scales.

* **Transportation u0026 Aerospace: ✈️�**

* **Automotive:** Electric power steering (EPS), throttle control, active suspension systems, automated gear shifting, brake-by-wire prototypes. Testing rigs for engines and components.

* **Aerospace:** Flight control surfaces (ailerons, rudders), engine control systems, landing gear actuation, simulation platforms.

* **Rail:** Traction motor control in modern trains, door operation.

* **Medical u0026 Life Sciences: ⚕️�**

* **Surgical Robots: �❤️** Providing tremor-free, scaled motion for minimally invasive procedures (e.g., Da Vinci system).

* **Medical Imaging:** Positioning patients and components in MRI, CT scanners, and X-ray machines with extreme precision.

* **Lab Automation:** Pipetting robots, sample handling systems, diagnostic equipment requiring precise fluid handling and movement.

* **Prosthetics u0026 Exoskeletons:** Providing natural, controlled movement for artificial limbs and assistive devices.

* **Dialysis Machines, Infusion Pumps:** Controlling fluid flow rates accurately.

* **Consumer Electronics u0026 Entertainment: ���**

* **Camera Gimbals u0026 Stabilizers:** Keeping video smooth even when moving.

* **3D Printers:** Precisely controlling the position of the print head and build platform.

* **Disk Drives:** Positioning the read/write head over spinning disks.

* **VR/AR Haptic Feedback:** Creating precise force feedback in controllers.

* **Advanced Appliances:** Precise control in washing machines, dishwashers, robotic vacuums.

* **Energy u0026 Sustainability: ��**

* **Solar Tracking:** Precisely orienting solar panels to follow the sun throughout the day for maximum energy capture.

* **Wind Turbines:** Pitch control of blades to optimize energy capture in varying wind speeds.

* **Battery Manufacturing:** Precise handling and processing of battery cells and materials.

**The Engine Room: Key Components Working in Harmony �**

A servo system isn't a single device; it's an orchestrated team:

1. **Controller:** This is the brain. It generates the motion command profile based on the programmed task and receives the feedback signals. It analyzes the error and calculates the precise corrective signal (usually a current or voltage command). Controllers range from simple modules to powerful multi-axis motion controllers running complex algorithms. Often integrated into a PLC or dedicated motion controller card.

2. **Servo Drive (Amplifier):** This is the powerhouse translator. It takes the low-power control signal from the controller and amplifies it significantly to provide the exact voltage and current required by the motor to execute the movement. It manages the complex power electronics (often using PWM - Pulse Width Modulation) and handles regenerative braking energy. Modern drives are packed with intelligence for tuning, diagnostics, and communication.

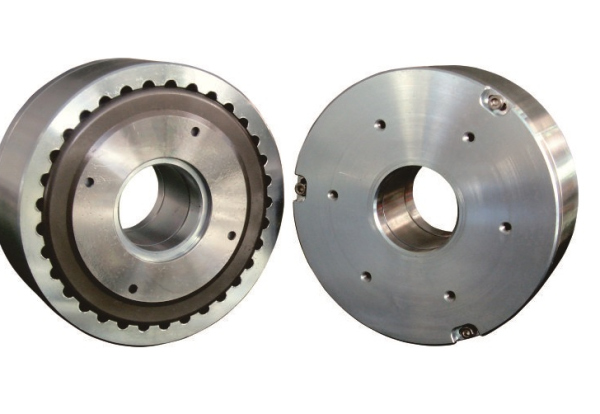

3. **Servo Motor:** This is the muscle. It converts the electrical energy from the drive into precise mechanical motion (rotation or linear movement). Designed for high torque at low speeds, rapid acceleration, and smooth operation. Key types include:

* **AC Brushless Servo Motors:** The most common industrial type. Efficient, reliable, high performance, low maintenance (no brushes). Excellent speed-torque characteristics.

* **DC Brush Servo Motors:** Simpler, often lower cost. Used in less demanding applications or smaller scales. Require brush maintenance.

* **Linear Servo Motors:** Produce straight-line motion directly, eliminating the need for mechanical conversions (like ball screws). Offer very high speeds and accelerations with exceptional precision.

4. **Feedback Device:** These are the eyes and ears. They provide the real-time data on the motor's actual position, speed, and sometimes torque, closing the critical loop. Common types:

* **Encoders:** Optical or magnetic devices that generate pulses corresponding to shaft rotation or linear displacement. Highly accurate. (Incremental for speed/relative position, Absolute for knowing position even after power loss).

* **Resolvers:** Robust analog devices that output sine/cosine signals representing shaft angle. Excellent in harsh environments (high temp, vibration, dust).

* **Tachometers:** Measure speed directly (usually generating a voltage proportional to RPM).

5. **Mechanical Transmission (Optional but Common):** Components like gearboxes (to increase torque or reduce speed), ball screws or lead screws (to convert rotary motion to linear motion), belts, pulleys, or linkages. These connect the motor's output to the load being moved. Their design and quality significantly impact the system's overall performance, accuracy, and stiffness.

**Choosing the Right Servo System: It's Not One-Size-Fits-All ✅**

Selecting the optimal servo solution requires careful consideration. A system perfect for a high-speed packaging robot would be overkill and overly expensive for a small 3D printer, and vice versa. https://www.validynamics.com/IMTS/ include:

* **Precision Requirements:** Micron level? Millimeter level? Accuracy and repeatability specs are paramount.

* **Speed u0026 Acceleration Needs:** How fast must it move? How quickly must it reach that speed?

* **Load Characteristics:** Mass, inertia, friction. How much force/torque is required to move the load? Does the load change dynamically?

* **Duty Cycle:** How often and for how long will the system operate at peak performance? Continuous operation requires robust cooling.

* **Environmental Conditions:** Temperature extremes? Dust, moisture, chemicals? Vibration or shock? This influences motor and feedback device choices (e.g., resolver vs. encoder).

* **Control Complexity:** Simple point-to-point movement, or complex multi-axis coordinated motion (e.g., contouring)? This dictates controller capabilities.

* **Communication u0026 Integration:** How will it connect to the overall machine controller (PLC)? Common protocols include EtherCAT, CANopen, Modbus TCP, Ethernet/IP, Profinet.

* **Size u0026 Form Factor Constraints:** Space limitations often dictate motor type and size.

* **Budget:** Balancing performance needs with cost-effectiveness.

**The Future is Servo: Trends Shaping Tomorrow's Precision ��⚡️**

Servo technology is far from static. It's evolving rapidly to meet the demands of smarter, more connected, and more efficient automation:

* **Integrated Motor Drives (IMDs):** Combining the drive electronics directly into the motor housing. Reduces wiring complexity, cabinet space, improves reliability, and minimizes electromagnetic interference (EMI). Simplifies installation.

* **Ethernet-Based Fieldbuses Dominating:** High-speed deterministic networks like EtherCAT continue to replace older serial buses. They enable faster cycle times, precise synchronization between multiple axes (nanosecond level), and simplified wiring harnesses.

* **Increased Intelligence at the Edge:** Servo drives are becoming smarter. Embedding more processing power allows for advanced diagnostics, predictive maintenance capabilities (monitoring vibration, temperature, current signatures), local motion control tasks offloading the central PLC, and adaptive tuning algorithms that adjust parameters automatically based on load or conditions.

* **Direct Drive Technology:** Eliminating mechanical transmissions (gearboxes, ball screws) by using high-torque direct-drive rotary motors or linear motors. This removes backlash, friction, and compliance issues, providing the ultimate in precision, stiffness, and responsiveness. Becoming more cost-competitive.

* **Focus on Energy Efficiency:** Regenerative drives are becoming standard. Further improvements in motor design (e.g., high-efficiency magnets, reduced losses) and drive efficiency (semiconductor technology) continue to reduce operating costs and environmental impact.

* **Simplified Tuning u0026 Commissioning:** User-friendly software tools, auto-tuning algorithms, and commissioning wizards are making it easier and faster to set up and optimize servo systems, even for complex applications. Reducing engineering time and expertise barriers.

* **Collaborative Robotics (Cobots):** Servo systems are fundamental to the smooth, precise, and force-limited movements required for safe human-robot interaction.

**Unlocking Your Potential: The Servo Advantage Awaits ��**

In a world where efficiency, quality, speed, and flexibility are non-negotiable competitive advantages, servo control systems are no longer a luxury—they are the engine of progress. They transform clunky automation into elegant precision engineering. They enable products that were previously impossible to manufacture consistently. They push the boundaries of speed and accuracy in research, medicine, and exploration.

Whether you're looking to:

* Eliminate costly production errors and scrap rates with unerring accuracy...

* Dramatically increase throughput with blistering speed and rapid changeovers...

* Handle delicate or complex products with gentle precision and consistent force...

* Automate intricate tasks that defy conventional mechanics...

* Build smarter, more adaptable, and energy-efficient machines...

* Pioneer new applications in cutting-edge fields...

...the servo control system is the foundational technology that makes it achievable and reliable.

**Beyond the Gearbox: It's About Capability �**

Don't think of a servo system as just another motor. Think of it as unlocking a new dimension of machine capability. It's the difference between a machine that merely functions and a machine that excels. It's the key to smoother operation, higher yields, reduced downtime, lower energy bills, and ultimately, a stronger competitive edge.

**Ready to Experience the Precision Revolution? �**

If the hum of inefficiency, the cost of inaccuracy, or the limitations of your current motion control are holding you back, it's time to explore the transformative power of modern servo technology. Leading manufacturers offer solutions tailored to every need, from compact integrated units to multi-megawatt powerhouses, backed by deep application expertise. Consultants and system integrators can help navigate the options and design the perfect solution for your specific challenge.

Stop settling for approximate. Embrace exact. Stop enduring sluggish. Embrace swift. Stop accepting inconsistent. Demand perfection. Unleash the precision, power, and intelligence of servo control systems, and propel your operations into a future defined by flawless execution. The technology is here. The potential is vast. The time to harness it is now. Let's build the future, precisely. ��⚡️