Engineering Excellence: Analyzing Market Dynamics in Aerospace Riveting Equipment Industry

Author : Amrut Mahajani | Published On : 07 May 2024

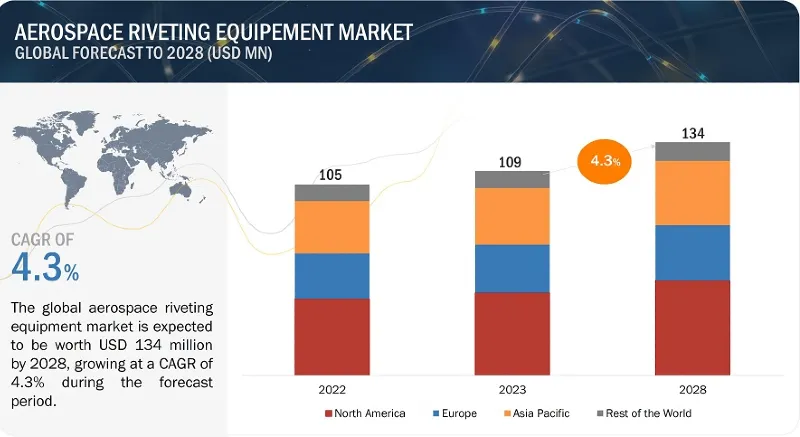

The Aerospace Riveting Equipment Industry is poised for growth, driven by the increasing demand for commercial aircraft and technological advancements in aerospace manufacturing. With a projected CAGR of 4.3%, the market is expected to reach USD 134 Million by 2028, up from USD 109 Million in 2023. This comprehensive analysis delves into the market's drivers, restraints, opportunities, and challenges, offering insights into the evolving landscape of aerospace riveting equipment.

The Aerospace Riveting Equipment Industry is poised for growth, driven by the increasing demand for commercial aircraft and technological advancements in aerospace manufacturing. With a projected CAGR of 4.3%, the market is expected to reach USD 134 Million by 2028, up from USD 109 Million in 2023. This comprehensive analysis delves into the market's drivers, restraints, opportunities, and challenges, offering insights into the evolving landscape of aerospace riveting equipment.

Market Size and Growth

The Aerospace Riveting Equipment Industry is on a growth trajectory, fueled by the rising demand for commercial aircraft worldwide. With air travel witnessing steady growth, the need for aerospace riveting equipment for manufacturing, assembling, and maintaining aircraft structures is on the rise. The market is projected to grow from USD 109 million in 2023 to USD 134 million by 2028, representing a CAGR of 4.3% during the forecast period.

Get a Deeper Understanding of the Industry by Visiting: https://www.marketsandmarkets.com/Market-Reports/aerospace-riveting-equipment-market-187704646.html

Market Trends

Technological Advancements in Aerospace Manufacturing: Continuous advancements in aerospace manufacturing technologies are driving the demand for innovative riveting equipment. As aircraft designs evolve to incorporate lightweight materials and intricate structures, precision in joining components becomes paramount. Technologies like laser riveting and friction stir welding offer solutions that enhance the strength, durability, and efficiency of aircraft structures. The increasing emphasis on fuel efficiency and demand for sophisticated aircraft further fuel the adoption of advanced riveting technologies.

Stringent Regulatory Compliance and Certification Standards: Navigating complex regulatory compliance and certification standards poses challenges for manufacturers of aerospace riveting equipment. Meeting evolving safety and quality standards requires continuous investment in research, testing, and documentation. The time-consuming nature of certification processes can impact the speed at which new riveting technologies can be brought to market.

Market Opportunities

Emerging Markets and Regional Expansion: Opportunities abound in emerging aerospace markets, particularly in regions like Asia-Pacific. Regional expansion strategies allow manufacturers to tap into new growth areas and cater to the evolving needs of regional aerospace industries. Establishing a presence in emerging markets fosters partnerships with local stakeholders and unlocks new avenues for business growth.

Market Challenges

Dependence on Aircraft Production Cycles: The aerospace riveting equipment market's dependence on aircraft production cycles introduces cyclicality in demand. Economic downturns or fluctuations in the aviation industry can impact new aircraft orders, affecting the market for riveting equipment. Manufacturers must manage production capacity and diversify product offerings to mitigate the impact of production cycle fluctuations.

Segment Overview

The Study Categorizes the Aerospace Riveting Equipment Market Based on Type, Platform, End User, and Region:

By Rivet Type:

- Blind Rivet

- Semi- Tubular Rivet

- Solid Rivet

- Other Rivet Types

By End Use:

- Original Equipment Manufacturers (OEM)

- Maintenance, Repair, and Overhaul (MRO)

By Equipment Type:

- Hydraulic Riveting Equipment

- Pneumatic Riveting Equipment

- Electric Riveting Equipment

By Mobility:

- Fixed Equipment

- Portable Equipment

By Technology:

- Automated Riveting Equipment

- Manual Riveting Equipment

By Region:

- North America

- Europe

- Asia Pacific

- Rest of the World

Equipment Segment Analysis: The market is segmented into hydraulic, pneumatic, and electric riveting equipment. Pneumatic riveting equipment leads the segment, driven by its efficiency and versatility in various industries. The demand for lightweight, durable, and secure joints in the aerospace sector fuels the adoption of pneumatic riveting tools.

End-Use Segment Analysis: OEMs lead the end-use segment, responsible for designing and manufacturing specific components or systems. OEMs strive to maintain high-quality standards through rigorous testing and adherence to industry standards, driving market growth.

Mobility Segment Analysis: Fixed equipment dominates the market, offering precision and stability in aircraft assembly. Aerospace manufacturers require reliable and stationary riveting solutions for critical assembly processes, driving demand for fixed riveting equipment.

Download Sample PDF Copy to Understand More: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=187704646

Regional Analysis

North America leads the market, hosting major aircraft manufacturers and suppliers. Stringent safety standards and emphasis on innovation drive demand for advanced riveting equipment in the region. North America's substantial investment in aerospace R&D further bolsters market growth.

Key Players

Globally established players such as Ingersoll Rand, Cherry Aerospace, Brown Aviation Tool Company, Stanley Engineered Fastening (SEF), and LAS Aerospace Ltd. dominate the Aerospace Riveting Equipment Market. These players focus on contracts, new product development, and compliance with government regulations to drive market growth.

The Aerospace Riveting Equipment Industry is poised for growth, driven by technological advancements, rising demand for commercial aircraft, and emerging aerospace markets. While navigating regulatory compliance and cyclicality in demand pose challenges, opportunities in emerging markets and regional expansion offer avenues for growth. With a focus on innovation and compliance, key players are shaping the future of aerospace riveting equipment, ensuring safety, reliability, and efficiency in aircraft manufacturing processes.

About MarketsandMarkets™

MarketsandMarkets™ has been recognized as one of America's best management consulting firms by Forbes, as per their recent report.

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

Earlier this year, we formally transformed into one of America's best management consulting firms as per a survey conducted by Forbes.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines - TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the 'GIVE Growth' principle, we work with several Forbes Global 2000 B2B companies - helping them stay relevant in a disruptive ecosystem. Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research. The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, and facilitates analysis of interconnections through applications, helping clients look at the entire ecosystem and understand the revenue shifts in their industry.

To learn more, visit www.MarketsandMarkets™.com or follow us on Twitter, LinkedIn and Facebook.

Contact:

Mr. Aashish Mehra

MarketsandMarkets™ INC.

630 Dundee Road

Suite 430

Northbrook, IL 60062

USA: +1-888-600-6441

Email: sales@marketsandmarkets.com