How to Buy Medical & Consumer Appliance Molds from China

Author : steven cheng | Published On : 16 Nov 2023

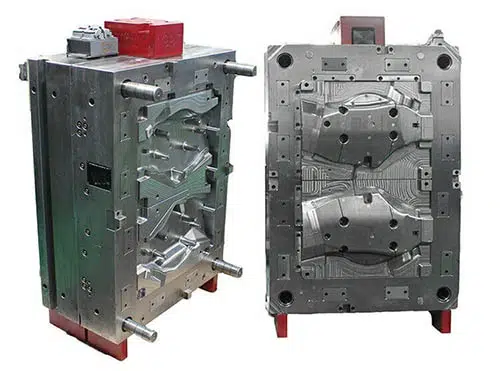

Buying injection molds for medical devices and consumer appliances from China can be a great way to reduce costs while still getting high-quality tools. Chinese mold makers have become experts at precision injection molds for all types of plastic parts and products. With some research and preparation on the front-end, you can find a trustworthy partner to produce your molds and make the process go smoothly from start to finish. Precision plastic molding enables next-gen medical tools. Leading mold makers like MyPlasticMold.com offer advanced medical injection molding to high standards. They also craft molds for consumer appliances. Custom appliance molds permit innovative features and accuracy.

This guide will walk you through the key steps of procuring medical and consumer appliance molds from China, including:

- Finding and vetting potential suppliers

- Evaluating mold quality and capabilities

- Understanding cost factors

- Managing the design, production and shipping process

- Ensuring quality control and protection of IP

Follow these tips and you'll be ready to tap into the skills of Chinese mold makers for your next project requiring precision plastic injection molds.

Finding and Vetting Medical & Consumer Appliance Mold Suppliers in China

The first step is identifying reputable manufacturers to partner with for your molds. Here are some tips for finding and vetting suppliers:

- Search Alibaba, Made-in-China.com and other directories for molded part/mold suppliers. Look for companies specializing in medical devices or consumer appliances.

- Check for experience with the type of tool you need - multi-cavity molds, overmolds, micromolds, etc. Look for case studies and product examples.

- Evaluate their capabilities - do they have in-house mold design, machining, finishing and quality control? This expertise is key.

- Assess their production capacity and technology. Look for smart, automated processes.

- Make sure they are compliant certified, at minimum to ISO 13485 for medical devices and ISO 9001 for consumer goods.

- Review testimonials and contact references to verify quality and service. A supplier should be transparent and forthcoming.

- Visit the facility in person for a quality audit if possible. Review their processes, management systems, quality control procedures, testing equipment, past molds, etc.

Taking these steps will help qualify suppliers capable of producing high-precision "Medical Injection Molding" and "Consumer Appliance Plastic Mold". Shortlist 2-3 top choices for further quote comparison.

Evaluating Medical & Consumer Appliance Mold Quality

When sourcing molds, quality should be the top priority - never sacrifice quality for cost. Here are key factors to evaluate:

Engineering & Design

- Sophisticated engineering skills - the supplier should optimize designs for manufacturability and provide DFMA analysis.

- Advanced mold simulation/analysis capabilities using Moldflow, CAD/CAM and CNC programming.

- Experience with the specific type of tool you need - multi-cavity, stack molds, overmolds, LSR molds, etc.

- Ability to precision machine complex geometries, micro features, delicate structures.

- Expertise with specialized materials like PEEK, ULTEM, PSU, etc if needed.

Machining & Manufacturing

- Precision CNC machining centers with strict process controls and comprehensive inspection.

- Skilled polishing and texturing capabilities for delicate cosmetic surfaces.

- Climate-controlled environment and contamination control procedures.

- Organized processes with digital systems for workflow management and traceability.

- Evidence of continuous improvement initiatives for enhanced consistency.

- Know-how with incorporating sensors, thermal controls, ejectors and other technologies into molds.

Testing & Validation

- Extensive measurement and testing protocols to validate tool geometry, dimensions, performance, etc.

- Capability to sample parts and test molding process independently before shipment.

- Experience with design of experiments (DOE) to fully optimize process parameters.

- Acceptance criteria aligned with your product requirements and industry standards.

- Willingness to remake/repair any defects rapidly at no cost.

These are the key markers of a high-quality mold supplier for medical and appliance applications. Be rigorous in the vetting process.

Understanding Cost Factors for Molds from China

When budgeting for your Chinese mold, here are some cost factors to consider:

- Mold base price - Determined by size, cavitation, complexity. Get quotes from multiple suppliers.

- Material costs - Tool steel, coatings, etc. Discuss specs with your supplier.

- Design fees - If needing design services, the supplier will charge fees.

- Simulation/analysis fees - Fees may apply for advanced simulation work.

- Rush fees - Faster lead times will increase cost. Discuss timeline.

- Testing/sampling fees - Some suppliers charge fees for testing and sampling parts.

- Shipping costs - Use sea freight for lower costs, air freight for faster transport.

- Import duties/taxes - Account for any import taxes/duties to your country.

- Payment terms - 30-50% downpayment is typical for most suppliers.

Get a detailed written quote accounting for these costs before confirming. Understand there can be +/- 10% variability. Having an open dialogue about costs and aligning expectations upfront is key for budgeting accurately.

Managing the China Mold Procurement Process

Careful project management is vital for successfully procuring molds from overseas. Here are tips for managing the process effectively:

Design & Engineering

- Provide complete design specs and requirements. Use models/drawings suitable for manufacturing.

- Collaborate on DFM refinements - trust your supplier's expertise.

- Align on design validation plan - simulation, mold flow analysis, prototypes, etc.

Production

- Define comprehensive quality plan - inspection points, verification protocols, acceptance criteria. Enforce strictly.

- Agree on timeline with clear milestones. Build in cushion for any delays or rework.

- Monitor progress closely with photos/video review. Visit for audits at key stages if possible.

Logistics

- Confirm shipping plan - carrier, route, insurance, import logistics.

- Track shipment status closely. Inspect thoroughly upon arrival before full payment.

Protection

- Use NNN agreements and contracts to protect payment terms, IP, confidentiality, etc.

- Require NDA from all supplier employees involved.

- Limit exchanged data. Watermark drawings/3D files.

Staying on top of every detail will ensure your China mold project stays on time, on budget and meets quality expectations.

Ensuring Quality Control & Protecting Intellectual Property

Two final critical considerations when sourcing molds from China are quality control and IP protection:

Quality Control

- Perform comprehensive incoming inspections - visual, dimensional, component validation tests.

- Require certifications of materials, processes used.

- Audit supplier's QC records - measurement, Cpk, testing data.

- Validate performance with process capability studies.

- Get commitments for fixing defects rapidly at no cost.

Intellectual Property Protection

- Use NNN contracts and clearly define ownership of IP. Require technology escrow if needed.

- Have supplier employees sign NDAs prohibiting unauthorized sharing of drawings, 3D models, etc.

- Limit data exchanged to only essential info. Watermark drawings/models.

- Obfuscate non-critical areas of part designs if possible.

- Consult a lawyer experienced in overseas manufacturing contracts as needed.

Following meticulous quality control and IP protection practices will ensure you receive a precision mold that meets requirements while protecting your critical manufacturing IP assets.

Conclusion

Sourcing high-quality medical and consumer appliance injection molds from China requires careful vetting of suppliers, validation of capabilities, disciplined project management and rigorous quality control. But the savings versus domestic tooling can make it very worthwhile if done right. By following this guide, you'll be prepared to secure premium precision molds from China cost-effectively and confidently. Remember to plan thoroughly, communicate expectations clearly, control the process tightly and verify quality relentlessly. Your Chinese supplier can become an invaluable long-term partner in bringing your manufactured products to market efficiently.